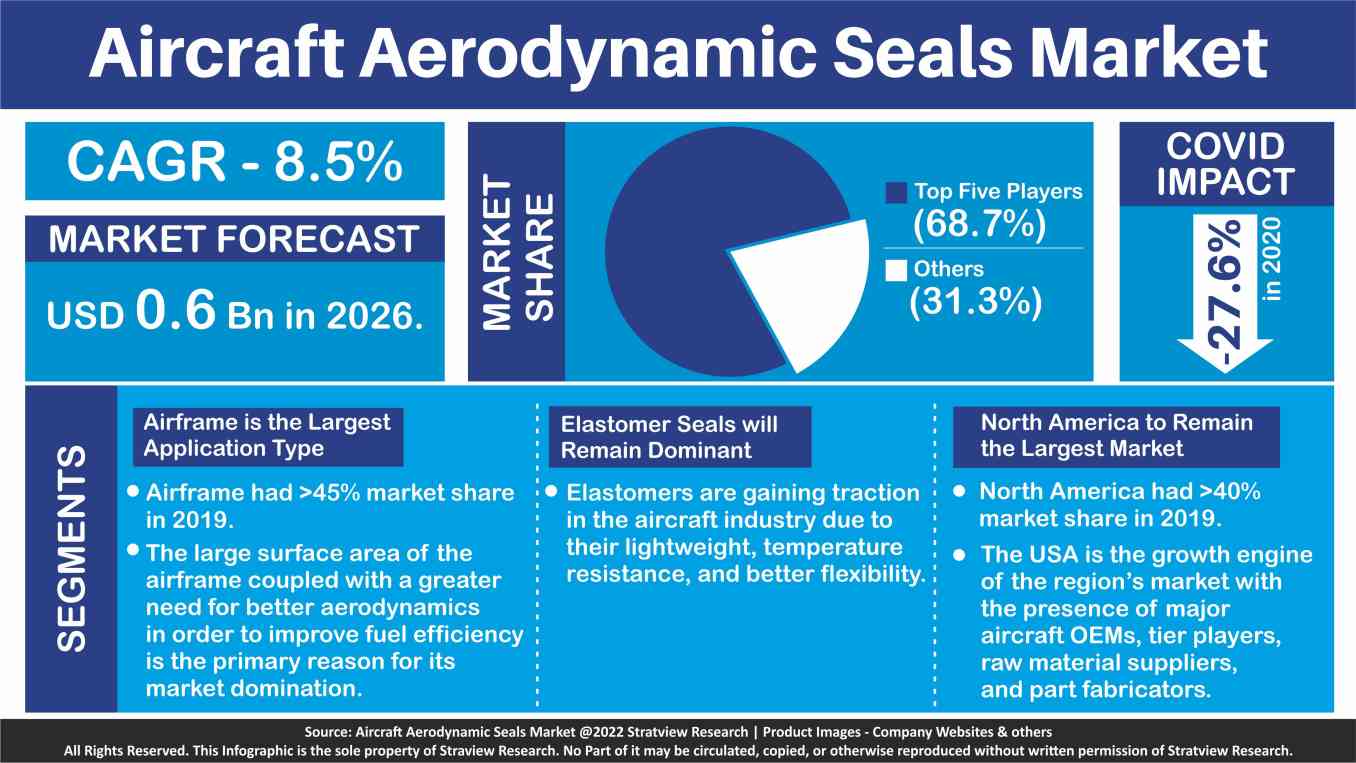

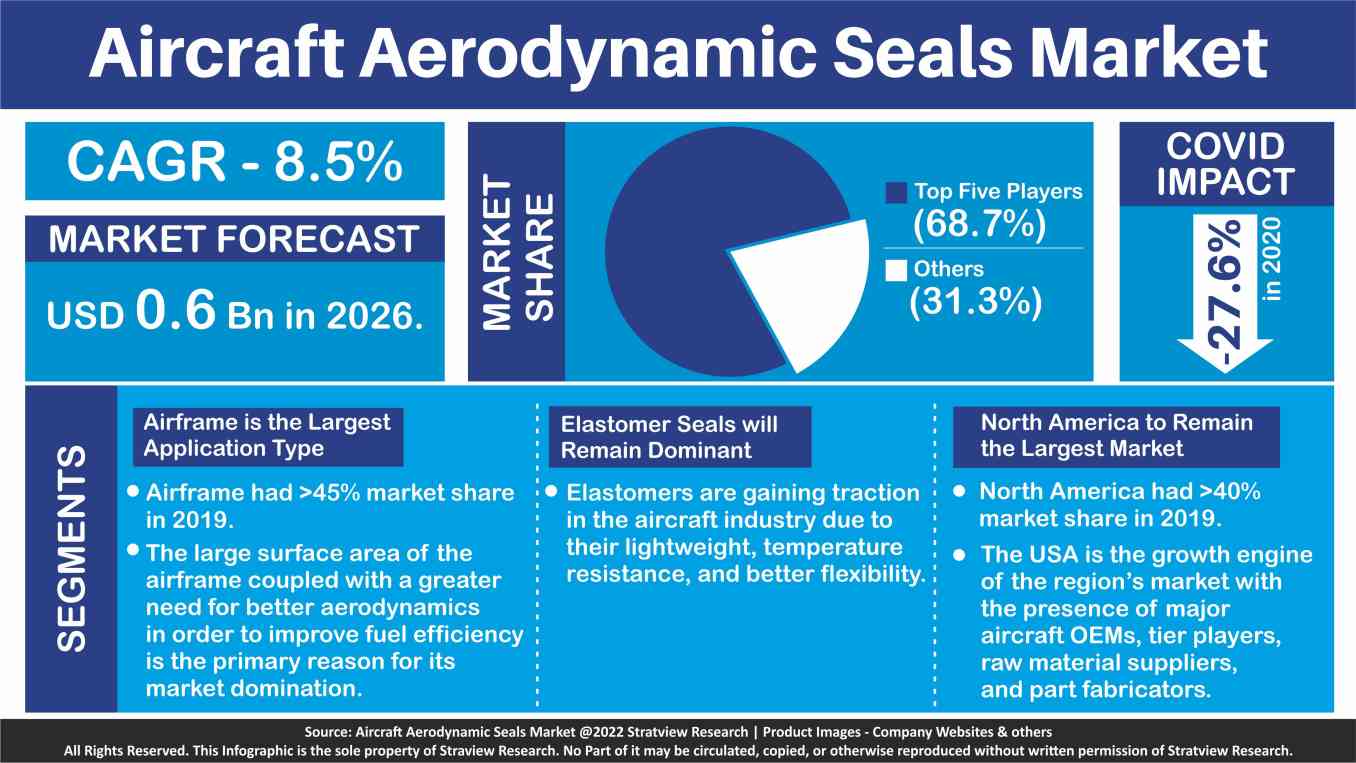

Aircraft Aerodynamic Seals Market Projected to Reach US$ 0.6 Billion in 2026.

Seals are used in multiple areas of an aircraft in order to serve a wide array of functions including aerodynamics, fire resistance, conduction, insulation, and air and fluid handling. Aerodynamic seals are the most widely used seals in an aircraft and account for almost half of the total aircraft seals market. These seals are statics seals that are used to control airflow between fixed portions of the airframe such as fuselage and wings. The selection of material is dependent on several parameters including temperature resistance, pressure resistance, lightweight, flexibility, durability, strength, etc. Elastomer, thermoplastic, and metal are the three major materials used by aerodynamic seals manufacturers. Elastomer is gaining traction in the market driven by its enormous advantages over others.

Seals have witnessed a remarkable transition in the aircraft industry over the eons concerning materials, designs, processes, certifications, and many other factors. Today, manufacturing seals for the aircraft industry for many functions including aerodynamics is a convoluted job, a key factor limiting the number of companies active in the aircraft seals market.

The aircraft aerodynamic seals market declined marginally from 2018 to 2019, mainly due to the industry concerns including fading air traffic growth, grounding of the B737 max, and delays in market entries of the most awaited programs, such as COMAC C919, Irkut MC-21, and Boeing B777x. The rapid spread of the pandemic entirely flipped the entire market dynamics, deepening the existing industry challenges including delays in B737 max approval and forcing aircraft manufacturers to curtail their key aircraft production. As a result of that, Stratview Research’s estimates suggest that the market for aircraft aerodynamic seals registered a hefty decline of -27.6% in 2020, taking the market below the level of 2015.

However, the long-term outlook still seems fruitful, well backed by the strong fundamentals. The lift of Boeing’s B737Max in October 2020, gradual opening up of travel restrictions, rebounding aircraft deliveries, and Airbus’ announcement of a gradual ramp-up in their aircraft production are among the few key factors signaling towards the industry’s take off to a healthy recuperation, helping the market stakeholders to grow at an encouraging rate of 8.5% to reach US$ 0.6 Billion in 2026.