Market Insights

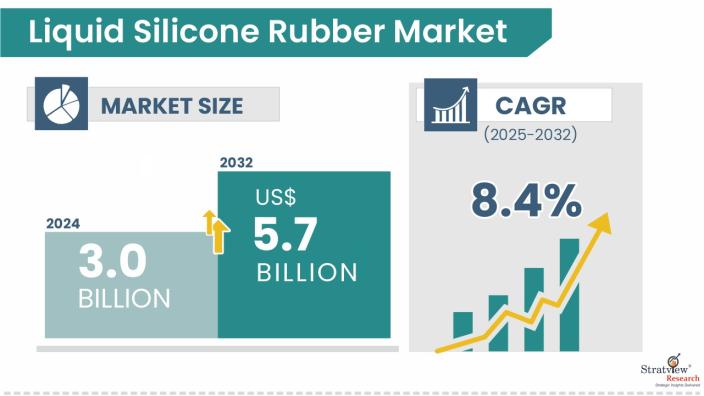

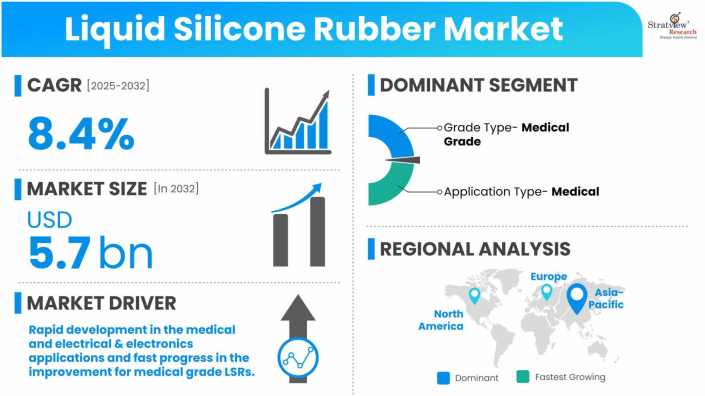

The liquid silicone rubber market was estimated at USD 3.0 billion in 2024 and is likely to grow at a CAGR of 8.4% during 2025-2032 to reach USD 5.7 billion in 2032.

Wish to get a free sample? Register Here

Market Dynamics

Introduction

Liquid silicone rubber is a type of silicone that is cured by platinum. Such a silicone type enjoys high stability and is known to have high resistance towards high temperatures. Liquid silicone rubber has its application in a number of areas such as automotive, medical, electronics, consumer goods, and others.

Market Drivers

Rapid development in the medical and electrical & electronics applications and fast progress in the improvement of medical-grade liquid silicone rubbers are the prime factors governing the global market. The engagement of medical-grade liquid silicone rubbers minimizes the hazard of bacterial contaminations and is henceforth employed in skin medications to support functionality and absorption. They are extensively used in electrical & electronics applications for electrical potting and insulation. Further, owing to their prime properties, such as chemical inertness and elevated temperature confrontation, they are also utilized in the engineering of LED lights.

Want to have a closer look at this market report? Click Here

Key Players

Some of the major players in the liquid silicone rubber market are:

- DOW Corning

- Wacker Chemie AG

- Momentive Performance Materials Inc.

- Shin-Etsu Chemical Co., Ltd.

- Bluestar Silicones (Elkem Group)

- KCC Corporation

- Nusil Technology LLC

- Simtec Silicone Parts, LLC

- Stockwell Elastomerics Inc.

- Zhejiang Xinan Chemical Industrial Group Co., Ltd.

- Reiss Manufacturing Inc.

Note: The above list does not necessarily include all the top players in the market.

Are you the leading player in this market? We would love to include your name. Write to us at sales@stratviewresearch.com

Segment Analysis

|

Segmentations

|

List of Sub-Segments

|

Segments with High Growth Opportunity

|

|

Grade Type Analysis

|

Industrial Grade, Medical Grade, and Food Grade

|

The medical-grade segment is estimated to grow at the highest rate in the coming five years.

|

|

Application Type Analysis

|

Automotive, Medical, Electrical & Electronics, Consumer Goods, and Others

|

The medical segment is estimated to be the fastest-growing application segment during the forecast period.

|

|

Regional Analysis

|

North America, Europe, Asia-Pacific, and Rest of the World

|

Asia-Pacific is the largest market for liquid silicone rubber.

|

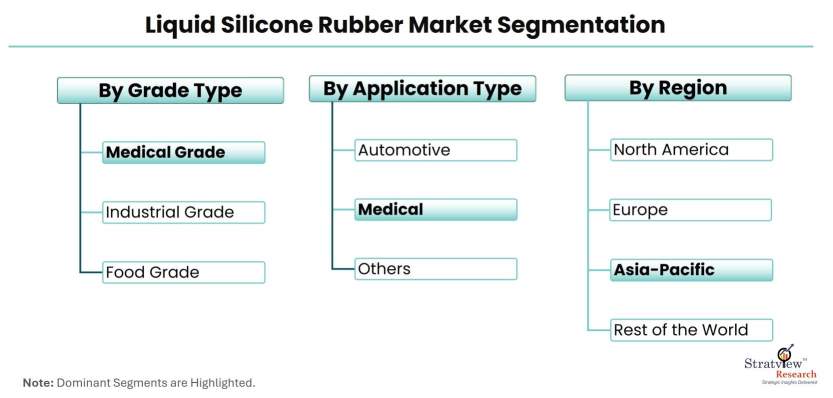

By Grade Type

Based on the grade type, the market is segmented as industrial grade, medical grade, and food grade. The medical-grade segment is estimated to grow at the highest rate in the coming five years. The growth is attributed to the rising elderly population across the board, coupled with the growing cognizance about health apprehensions, which is driving the medical applications segment. As grades are subjected to various approvals and protocols for practice in the medical sector, these are more expensive than other grades. Hence, the medical-grade segment is projected to be the largest segment during the forecast period.

By Application Type

Based on the application type, the market is segmented as automotive, medical, electrical & electronics, consumer goods, and others. The medical segment is estimated to be the fastest-growing application segment during the forecast period, in terms of both value and volume. The growth is attributed to the growing demand for throwaway medical devices and implants.

Regional Insights

In terms of regions, Asia-Pacific is the largest market for liquid silicone rubber. The region is likely to maintain its dominance during the forecast period. China and India are the growth engines of the region. China is estimated to be the largest, while India is estimated to be the fastest-growing market in the coming five years. The market is driven by the presence of global manufacturing giants in the region. North America is also estimated to be the fastest-growing market for liquid silicone rubber during the forecast period. The USA is the fastest-growing market in the region. The market is sustained by the increasing demand for implants, disposable medical devices, and equipment parts.

Know the high-growth countries in this report. Register Here

Research Methodology

This strategic assessment report, from Stratview Research, provides a comprehensive analysis that reflects today’s liquid silicone rubber market realities and future market possibilities for the forecast period of 2025 to 2032. After a continuous interest in our liquid silicone rubber market report from the industry stakeholders, we have tried to further accentuate our research scope to the liquid silicone rubber market to provide the most crystal-clear picture of the market. The report segments and analyses the market in the most detailed manner to provide a panoramic view of the market. The vital data/information provided in the report can play a crucial role for the market participants as well as investors in the identification of the low-hanging fruits available in the market as well as to formulate the growth strategies to expedite their growth process.

This report offers high-quality insights and is the outcome of a detailed research methodology comprising extensive secondary research, rigorous primary interviews with industry stakeholders, and validation and triangulation with Stratview Research’s internal database and statistical tools. More than 1000 authenticated secondary sources, such as company annual reports, fact books, press releases, journals, investor presentations, white papers, patents, and articles, have been leveraged to gather the data. We conducted more than 15 detailed primary interviews with the market players across the value chain in all four regions and industry experts to obtain both qualitative and quantitative insights.

Report Features

This report provides market intelligence in the most comprehensive way. The report structure has been kept such that it offers maximum business value. It provides critical insights into market dynamics and will enable strategic decision-making for existing market players as well as those willing to enter the market. The following are the key features of the report:

- Market structure: Overview, industry life cycle analysis, supply chain analysis.

- Market environment analysis: Growth drivers and constraints, Porter’s five forces analysis, SWOT analysis.

- Market trend and forecast analysis.

- Market segment trend and forecast.

- Competitive landscape and dynamics: Market share, Service portfolio, New Product Launches, etc.

- COVID-19 impact and its recovery curve

- Attractive market segments and associated growth opportunities.

- Emerging trends.

- Strategic growth opportunities for the existing and new players.

- Key success factors

Market Segmentation

This report studies the market, covering a period of 12 years of trends and forecasts. The report provides detailed insights into the market dynamics to enable informed business decision-making and growth strategy formulation based on the opportunities present in the market.

The liquid silicone rubber market is segmented into the following categories.

By Molding Technology Type

- Liquid Injection Molding System

- (Molding Technology Type Analysis: Molding Process)

By Grade Type

- Industrial Grade

- Medical Grade

- Food Grade

By Application Type

- Automotive

- (Application Type Analysis: Components and Automotive Parts)

- Medical

- (Application Type Analysis: Implants, Medical Devices, and Medical Equipment Parts)

- Electrical & Electronics

- (Application Type Analysis: Electrical Insulation and Electrical & Optical Components)

- Consumer Goods

- (Application Type Analysis: Home Appliance Components, Food Contact Products, Water Contact Products, and Infant Care Products)

- Others

- (Application Type Analysis: Cosmetic Applications, Building & Construction, Aerospace & Aeronautics, and Industrial Components)

By Region

- North America (Country Analysis: the USA, Canada, and Mexico)

- Europe (Country Analysis: Germany, France, the UK, Russia, and Rest of Europe)

- Asia-Pacific (Country Analysis: China, Japan, India, and Rest of Asia-Pacific)

- Rest of the World (Sub-Region Analysis: Latin America, the Middle East, and Others)

Click Here, to learn the market segmentation details.

Report Customization Options

With this detailed report, Stratview Research offers one of the following free customization options to our respectable clients:

Company Profiling

- Detailed profiling of additional market players (up to 3 players)

- SWOT analysis of key players (up to 3 players)

Market Segmentation

- Current market segmentation of any one of the molding technology types by application type.

Competitive Benchmarking

- Benchmarking of key players on the following parameters: Product portfolio, geographical reach, regional presence, and strategic alliances.

Custom Research: Stratview Research offers custom research services across sectors. In case of any custom research requirement related to market assessment, competitive benchmarking, sourcing and procurement, target screening, and others, please send your inquiry to sales@stratviewresearch.com.