Attractive Opportunities

Global Demand Analysis & Sales Opportunities in EV Nonwoven Composite Market

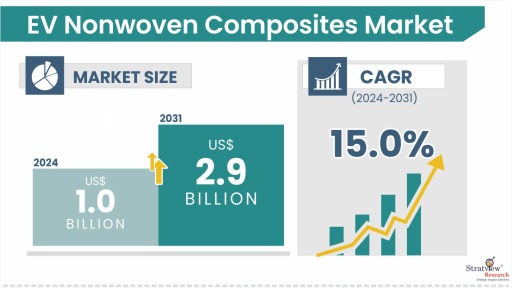

- The annual demand for EV nonwoven composite was USD 1.0 billion in 2024 and is expected to reach USD 1.3 billion in 2025, up 22.1% than the value in 2024.

- During the forecast period (2025-2031), the EV nonwoven composite market is expected to grow at a CAGR of 15.0%. The annual demand will reach USD 2.9 billion in 2031, which is more than 2 times the demand in 2025.

- During 2025-2031, the EV nonwoven composite industry is expected to generate a cumulative sales opportunity of USD 14.9 billion, which is almost 5 times the opportunities during 2019-2024.

Want to get a free sample? Register Here

High-Growth Market Segments:

- Asia-Pacific is expected to hold the largest market share over the forecast period.

- By application type, Trunk is expected to be the demand generator for the EV Nonwoven Composites market in the coming years.

- By end-use industry type, BEV is likely to grow at a faster rate in the market over the forecasted years.

- By material type, Fiberglass Composites are anticipated to be the preferred material of the market.

- By matrix/builder type, Biocomponent PET/coPET is expected to be the fastest-growing segment of the market in the coming years.

- By formation type, Drylaid holds the largest market share for EV nonwoven composites over the forecasted period

Market Statistics

Have a look at the sales opportunities presented by the EV nonwoven composite market in terms of growth and market forecast.

|

EV Nonwoven Composite Market Data & Statistics

|

|

|

Market Statistics

|

Value (in USD Billion)

|

Market Growth (%)

|

|

Annual Market Size in 2023

|

USD 0.8 billion

|

-

|

|

Annual Market Size in 2024

|

USD 1.0 billion

|

YoY Growth in 2024: 22.9%

|

|

Annual Market Size in 2025

|

USD 1.3 billion

|

YoY Growth in 2025: 22.1%

|

|

Annual Market Size in 2031

|

USD 2.9 billion

|

CAGR 2025-2031: 15.0%

|

|

Cumulative Sales Opportunity during 2025-2031

|

USD 14.9 billion

|

|

|

Top 10 Countries’ Market Share in 2024

|

USD 0.8 billion +

|

> 80%

|

|

Top 10 Company’s Market Share in 2024

|

USD 0.5 billion to USD 0.7 billion

|

50% - 70

|

Market dynamics

Introduction:

Nonwoven composites used in electric vehicles (EVs) are advanced materials made by combining nonwoven fabrics with resins, binders, or reinforcement fibers to enhance strength, durability, and functionality. These composites are widely used in interior and structural applications such as carpets, insulation, trunk liners, and underbody shields. Their lightweight nature, acoustic insulation, thermal resistance, and recyclability make them ideal for improving energy efficiency and sustainability in EVs. As the EV industry grows, demand for high-performance, eco-friendly nonwoven composites continues to rise.

Market Drivers:

- The market for nonwoven composites in electric vehicles (EVs) is driven by the growing demand for lightweight materials that enhance energy efficiency and extend driving range. Nonwoven composites offer an excellent strength-to-weight ratio, making them ideal for EV applications such as battery insulation, interior components, and underbody protection. Their acoustic and thermal insulation properties improve passenger comfort and battery performance.

- Strict government regulations on emissions and sustainability are pushing automakers to adopt recyclable and bio-based nonwoven composites, further fueling market growth.

- Another key driver is the rapid expansion of the EV industry, supported by government incentives, technological advancements, and rising consumer demand for eco-friendly vehicles. Nonwoven composites enhance vehicle safety, durability, and design flexibility, making them essential in structural and interior applications.

- Advances in manufacturing processes allow for cost-effective production, increasing their adoption of mass-produced EVs. Additionally, growing investments in research and development for fire-resistant and high-performance composites further drive innovation and market expansion.

Segments' Analysis

|

Segmentations

|

List of Sub-Segments

|

Segments with High-Growth Opportunity

|

|

Application-Type Analysis

|

Door Panel, Trunk, Packaged Tray, Headliner, Underbody Shield, Wheel Arch Liners, Center Console, and Other Applications.

|

Trunk is expected to be the demand generator for the EV Nonwoven Composites market in the coming years.

|

|

End-Use Industry-Type Analysis

|

BEV and Hybrid

|

BEV is likely to grow at a faster rate in the market over the forecasted years.

|

|

Material-Type Analysis

|

Fiberglass Composites, Natural/Wood Fiber Composites, Polyester Fiber Composites, Carbon Fiber Composites, and Other Composites

|

Fiberglass Composites are anticipated to be the preferred material of the market.

|

|

Matrix/Binder-Type Analysis

|

Biocomponent PET/coPET, Polypropylene, and Other Matrix/Binders

|

Biocomponent PET/coPET is expected to be the fastest-growing segment of the market in the coming years.

|

|

Formation-Type Analysis

|

Spunlaid, Drylaid, and Other Formations

|

Drylaid holds the largest market share for EV nonwoven composites over the forecasted period.

|

|

Region Analysis

|

North America, Europe, Asia-Pacific, and The Rest of the World

|

The Asia-Pacific is expected to hold the largest market share over the forecast period.

|

Application Insights

“Trunks are expected to remain the dominant application of the EV nonwoven composites market during the forecast period.”

- Based on application, the market is segmented into door panel, trunk, packaged tray, headliner, underbody shield, wheel arch liners, center console, and other applications. Trunk will continue to be the leading application for EV nonwoven composites. Nonwoven composites provide lightweight yet strong solutions, enhancing impact resistance, noise reduction, and thermal insulation in trunk components.

- The growing demand for sustainable and recyclable materials in EV manufacturing supports the adoption of nonwoven composites. As EV production surges, manufacturers prioritize efficient space utilization and lightweight designs, making nonwoven composites an ideal choice for trunk liners and structural reinforcements.

End-Use Industry Insights

“BEV is expected to remain the fastest-growing end-use industry of the EV nonwoven composites market during the forecast period.”

- Based on the vehicle type, the automotive nonwoven composites market is segmented into BEV and Hybrid.

- BEVs represent the most rapidly expanding category for EV nonwoven composites, with growing adoption fueled by government incentives and emission standards. Their requirement for light materials boosts battery efficiency and range. BEVs use greater quantities of nonwoven composites in battery enclosures, interiors, and thermal management. The materials are cost-effective, durable, and provide better insulation.

- Technological advancements in nonwoven composites further accelerate integration. Increased demand from consumer desire for zero-emission vehicles pushes growth. Together, these factors propel the fast expansion of nonwoven composites in BEVs.

Material Insights

“Fiberglass composites are expected to hold the largest share of the market during the forecast period.”

- Based on the material type, the market is segmented into fiberglass composites, natural/wood fiber composites, polyester fiber composites, carbon fiber composites, and other Composites.

- Fiberglass composites are anticipated to dominate the market with the highest share because they possess exceptional properties and extensive use in EVs. They have a high strength-to-weight ratio, which makes structural integrity higher while minimizing vehicle weight. Their high durability and corrosion resistance make them perfect for prolonged use.

- Fiberglass composites also have exceptional thermal and sound insulation, which is important in EV efficiency and comfort. Also, they are economical in comparison to carbon fiber, and thus, they are a manufacturer's choice. Their use in applications like battery enclosures, trunk parts, and interior components further enhances their dominance.

Matrix/Binder Insights

“Biocomponent PET/coPET is expected to remain the fastest-growing segment for the EV nonwoven composites market during the forecast period.”

- Based on the matrix type, the market is segmented into bicomponent PET/coPET fiber, polypropylene, and other Matrix/Binders.

- Biocomponent PET/coPET is likely to be the most rapidly growing matrix segment for EV nonwoven composites owing to its superior performance and sustainability advantage. It exhibits good bonding qualities, improving the structural strength of EV parts. Its lightness improves vehicle efficiency and battery life. The material has better thermal and acoustic insulation, which is important for EV interiors and protecting batteries.

- Moreover, its recyclability fits with the sustainability objective of the automobile industry. As the demand for green and high-performance materials increases, Biocomponent PET/coPET will be quick to gain adoption in EV nonwoven composites.

Regional Insights

“Asia-Pacific is expected to hold the largest share of the EV nonwoven composites market during the forecast period.”

- Asia-Pacific leads the EV nonwoven composites market because it is a world leader in EV manufacturing, and China, Japan, and South Korea are in the lead. The region is supported by an extensive automotive supply chain, facilitating low-cost production.

- Government subsidies, policies, and emissions control push EV growth, fueling composite demand. Urbanization and growing consumer needs also increase EV sales.

- Labor and production expenses are lower, making Asia-Pacific a cost-competitive manufacturing region. R&D and innovation investments improve material performance and efficiency. These, as a whole, support the region's market leadership.

Want to get a free sample? Register Here

Competitive Landscape

The market is highly fragmented, with over 200 players. Most of the major players compete in some of the governing factors, including price, service offerings, regional presence, etc. The following are the key players in the EV nonwoven composites market. Some of the major players provide a complete range of services:

Here is the list of the Top Players (Based on Dominance)

-

Fibertex Group

-

Freudenberg Group

-

Milliken & Company

-

TWE Group

-

Rochling Group

-

Glatfelter Corporation

-

Asahi Kasei Corporation

-

Ahlstrom Oyj

Note: The above list does not necessarily include all the top players in the market.

Are you the leading player in this market? We would love to include your name. Please write to us at sales@stratviewresearch.com

Report Features

This report provides market intelligence most comprehensively. The report structure has been kept so that it offers maximum business value. It provides critical insights into market dynamics and will enable strategic decision-making for existing market players as well as those willing to enter the market.

The following are the key features of the report:

- Market structure: Overview, industry life cycle analysis, supply chain analysis.

- Market environment analysis: Growth drivers and constraints, Porter’s five forces analysis, SWOT analysis.

- Market trend and forecast analysis.

- Market segment trend and forecast.

- Competitive landscape and dynamics: Market share, Service portfolio, New Product Launches, etc.

- COVID-19 impact and its recovery curve.

- Attractive market segments and associated growth opportunities.

- Emerging trends.

- Strategic growth opportunities for the existing and new players.

- Key success factors.

|

Market Study Period

|

2019-2031

|

|

Base Year

|

2024

|

|

Forecast Period

|

2025-2031

|

|

Trend Period

|

2019-2023

|

|

Number of Tables & Figures

|

>100

|

|

Number of Segments Analysed

|

6 (Application Type, End-Use Industry Type, Material Type, Matrix Type, Formation Type, and Region)

|

|

Number of Regions Analysed

|

4 (North America, Europe, Asia-Pacific, Rest of the World)

|

|

Countries Analysed

|

15 (The USA, Canada, Mexico, Germany, France, Italy, The UK, China, Japan, India, Brazil, Saudi Arabia, Rest of Europe, Rest of APAC, and Rest of the World)

|

|

Free Customization Offered

|

10%

|

|

After Sales Support

|

Unlimited

|

|

Report Presentation

|

Complimentary

|

|

Market Dataset

|

Complimentary

|

|

Further Deep Dive & Consulting Services

|

10% Discount

|

Market Segmentation

This report studies the market, covering a period of 15 years of trend and forecast. The report provides detailed insights into the market dynamics to enable informed business decision-making and growth strategy formulation based on the opportunities present in the market.

The global EV nonwoven composite market is segmented into the following categories:

EV Nonwoven Composite Market, by Application Type

- Door Panel

- Trunk

- Packaged Tray

- Headliner

- Underbody shield

- Wheel Arch Liners

- Center Console

- Other Applications

EV Nonwoven Composite Market, by End Use

EV Nonwoven Composite Market, by Material Type

- Fiberglass Composites

- Natural/Wood Fiber Composites

- Polyester Fiber Composites

- Carbon Fiber Composites

- Other composites (Hybrid, Aramids, Basalt, etc.)

EV Nonwoven Composite Market, by Matrix/Binder Formation

- Biocomponent PET/coPET

- Polypropylene

- Other Matrix/Binders

EV Nonwoven Composite Market, by Formation Type

- Spunlaid

- Drylaid

- Other Formations

EV Nonwoven Composite Market, by Region

- North America (Country Analysis: The USA, Canada, and Mexico)

- Europe (Country Analysis: Germany, France, Turkey, Russia, and Rest of Europe)

- Asia-Pacific (Country Analysis: Japan, China, India, and Rest of Asia-Pacific)

- Rest of the World (Country Analysis: Brazil, Argentina, and Others)

Research Methodology

- This strategic assessment report from Stratview Research provides a comprehensive analysis that reflects today’s EV nonwoven composite market realities and future market possibilities for the forecast period

- The report segments and analyzes the market in the most detailed manner to provide a panoramic view of the market.

- The vital data/information provided in the report can play a crucial role for market participants and investors in identifying the low-hanging fruits available in the market and formulating growth strategies to expedite their growth process.

- This report offers high-quality insights and is the outcome of a detailed research methodology comprising extensive secondary research, rigorous primary interviews with industry stakeholders, and validation and triangulation with Stratview Research’s internal database and statistical tools.

- More than 1,000 authenticated secondary sources, such as company annual reports, fact books, press releases, journals, investor presentations, white papers, patents, and articles, have been leveraged to gather the data.

- We conducted more than 15 detailed primary interviews with market players across the value chain in all four regions and industry experts to obtain both qualitative and quantitative insights.

Customization Options

With this detailed report, Stratview Research offers one of the following free customization options to our respectable clients:

Company Profiling

Competitive Benchmarking

-

Benchmarking of key players based on the following parameters: Product portfolio, geographical reach, regional presence, and strategic alliances

Custom Research: Stratview Research offers custom research services across sectors. In case of any custom research requirement related to market assessment, competitive benchmarking, sourcing and procurement, target screening, and others, please send your inquiry to sales@stratviewresearch.com