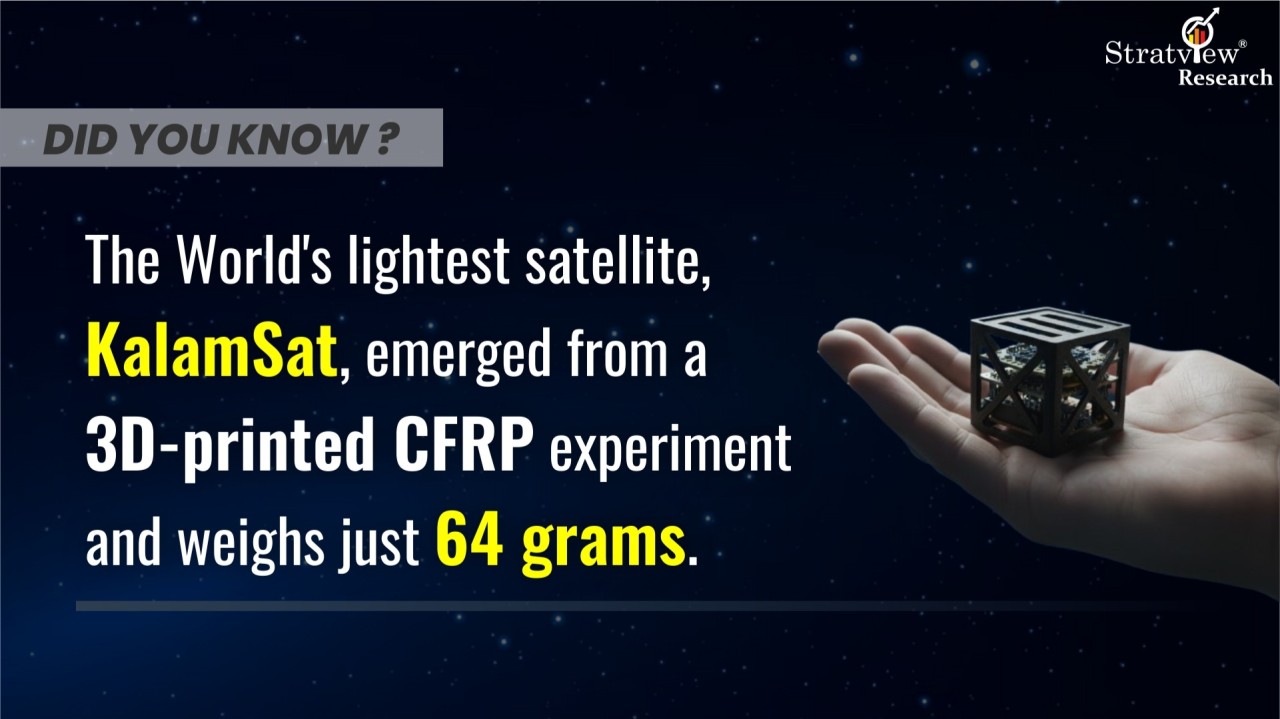

A satellite weighing less than a cricket tennis ball? Yes, you read it right. Meet KalamSat - the world’s lightest satellite at just 64 grams. Created by an 18-year-old student, this tiny cube is fully 3D-printed from carbon fiber-reinforced polymer (CFRP), carries real scientific experiments, and spent over 200 minutes in space. It’s a story that proves innovation has no age, no boundaries, and certainly no weight limit.

A Dream That Took Flight

Rifath Sharook challenged a long-held industry assumption: Does a satellite need size to deliver capability?

For most people, this would remain a passing thought. Instead of letting the question fade, he engineered an entirely new benchmark. Together with his team, he developed a palm-sized platform capable of performing legitimate scientific experiments in microgravity, demonstrating that functional space hardware doesn’t need bulk to create impact.

Their innovation, KalamSat, won the NASA-supported Cubes in Space competition – a platform where students design experiments for suborbital flight, reinforcing the team’s technical credibility on a global stage.

More importantly, it introduced a world first: the first fully 3D-printed satellite built using carbon fiber-reinforced polymer (CFRP), redefining what lightweight space systems can achieve.

CFRP – Behind the Miracle in 64 Grams

The satellite is a 3.8 cm cube, designed completely from scratch using locally sourced materials. Inside this tiny frame, the team had to pack:

-

A new onboard computer

-

8 sensors to measure temperature, humidity, magnetosphere, rotation, and more

-

A nano Geiger-Muller counter for radiation measurement

All while staying within the 64-gram limit, a challenge most engineers would consider nearly impossible.

How did they achieve? The main frame was not made of traditional aerospace aluminium or titanium, but rather a carbon fiber reinforced polymer (CFRP) composite. Composites combine exceptional strength with lightweight properties, which is critical for space applications to reduce launch costs.

The structure was fabricated using 3D printing technology. 3D printing allowed the KalamSat team to eliminate excess material and build only the structural geometry required for functional strength.

A Journey to Space

In June 2017, a NASA sounding rocket carried KalamSat into space from Wallops Island, Virginia. The mission lasted 240 minutes, including 125 minutes in microgravity, where the primary experiment took place: testing how 3D-printed CFRP behaves in space.

After separation, KalamSat fell into the sea and will be recovered for data decoding, marking the completion of a historic flight.

A Small Cube, A Giant Leap

From minisats weighing hundreds of kilograms to microsats, nanosats, and picosats, the pyramid of small satellites narrows down to the lightest of all - femtosats under 100 grams. KalamSat sits in this FemtoSat category, redefining what’s possible at the smallest scale. With 2,800+ smallsats launched in 2024, the shift toward compact, composite-built satellites is accelerating fast. And KalamSat stands as proof that innovation doesn’t always arrive on giant rockets - sometimes, it fits in the palm of your hand. Its feather-light design reflects a future where aerospace composites and ultra-compact satellites reshape how we track, predict, and respond to Earth’s changing systems.

Curious to know more about small satellites? Click Here...