According to the insights by Stratview Research, the tire yarn market is projected to grow at a 4% CAGR over the next five years, approaching US$ 4.0 billion by 2024. Automotive remains the top consumer, followed by tractors, earthmovers, and industrial vehicles. The aircraft segment, though small, is set to expand at a 5% CAGR.

With increasing focus of the world economies, on reduction of greenhouse gas emissions, achieving fuel efficiency to meet emission norms has been the focal area of automobile manufacturing. Innovative light weight tires, with lower rolling resistance helps in achieving considerable fuel economies.

Technical textiles have evolved over the years to improve their functionality and use in various industrial applications. One of the applications of manmade technical fabrics is tire yarn. Textiles are used as tire reinforcement materials for strength and improving dimensional stability of the tire. They are made primarily of polyester, polyamide, aramid and rayon. Innovation in use of tire yarns has helped tire manufacturers reduce the weight and rolling resistance of tires.

Cotton was the first textile material to be used in tires, which gradually got replaced with Rayon. However, due to their many beneficial properties, Polyamide and Polyester are now the materials of choice for tire makers. These cords and fabrics are used in various parts of the tire, where they help sustaining the high level of strain, deformation and temperature observed in a running tire, especially at a high speed. They are mainly used as reinforcement materials in carcass (or Cord ply), cap ply (or overlay), bead protection, chaffer and side walls.

Cord Ply, is a major application of tire yarn as it is the strength element of the tire and controls the internal pressure and maintains the tire’s shape. Polyamide is the chosen material in cord ply as it offers high tensile strength, adhesion to rubber and high dimensional stability.

Automotive Industry – The Largest Consumer of Tire Yarns

The tire yarn market is expected to grow at annual CAGR of 4% over the next 5 years, reaching nearly US$ 4.0 billion by 2024. The automotive sector is the largest consumer of tire yarns followed by speciality vehicles like tractors, earth moving vehicles and industrial vehicles. Aircraft Industry has a minimal share in the tire yarn segment but is expected to grow at 5% (CAGR) in the next five years.

China, USA, Germany, Japan and Brazil account for more than 50% of the tire yarn market. Although, there is a demand slump in automobile sector, but with expected recovery in the coming five years, China, Japan and India will be driving the growth of tire yarns. In addition, with Airbus planning new aircraft, Europe is expected to register good growth in the tire yarn market.

The Global tire yarn market is highly consolidated with top 5 players (Kordsa Teknik Tekstil, Shenma Industrial Co., Ltd., Hyosung Corporation, Indorama Ventures PLC and Kolon Industries Inc) capturing three-fourths of the total market in 2018.

Changing Dynamics of Tire Manufacturing Fuelling Demand for Tire Yarn

Passenger car makers are increasing the rims of the tires to 15”-17” in both high end and basic segments, for making their vehicles look more attractive and appealing to customers. The increased rim size, increases the use of cord ply, cap ply and bead reinforcement, improving the demand for tire yarn. Also, weight reduction of tires has increased the demand for single ply casings.

Improving rolling resistance (energy consumed by the tire per unit distance) has been the central focus of tire manufacturers. It is one of the forces that acts to oppose the motion of a driver. The main reason for this is - when the tires are in motion and touch the surface, the shape of the tires changes and causes deformation. This results in loss of energy due to heat which is termed as hysteresis. To overcome this, more force is needed (fuel in case of vehicles) to push the tire over the surface. Lower rolling resistance helps in reduction in fuel consumption by 6%-8%. This has resulted in boosting the demand for high tech yarns and cap ply.

Polyamide Yarn Reigns the Market

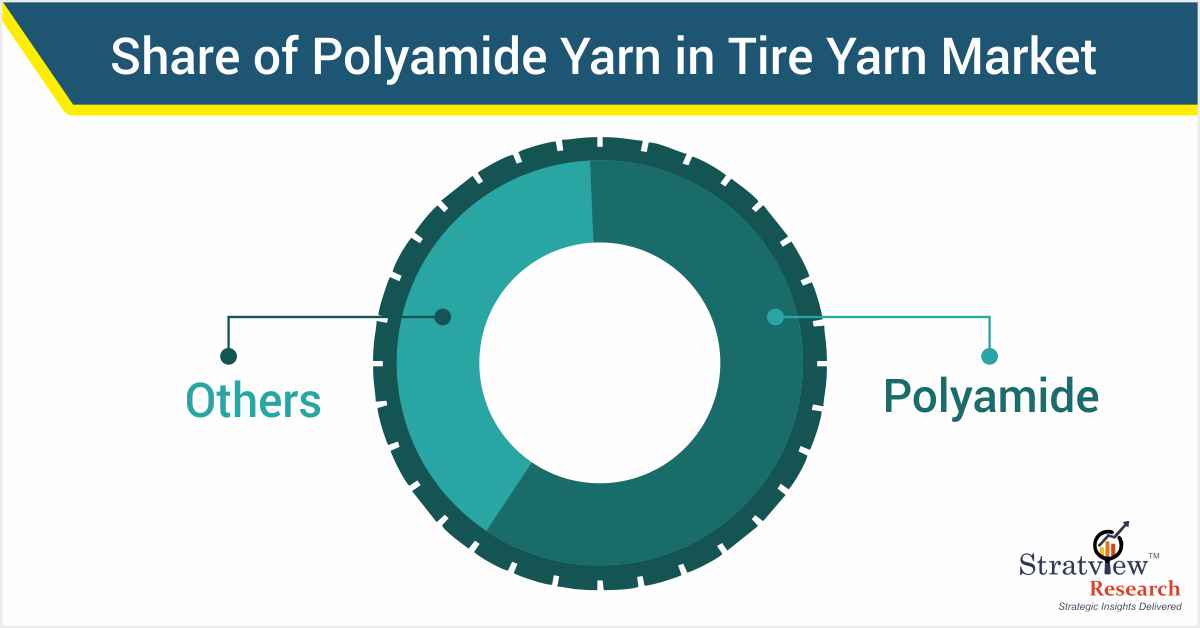

Polyamide (PA6, PA66) yarn is the material of choice in tire reinforcement, capturing more than 50% market, due to its superior properties of high tenacity, toughness, and fatigue resistance. Polyamide is widely used for cap ply and bead reinforcements in cross ply tires in heavy duty trucks, off-road vehicles and aircraft tires.

Figure : Share of Polyamide Yarn in Tire Yarn Market

Polyester yarn is used in radial tires and is a preferred choice for passenger car tires and light truck tires. Polyester tire yarn rapidly loses its properties at tire temperatures over 120 degrees Celsius and hence, is not used in high speed, high load and high temperature applications. With increasing shift to radial tires, the demand for polyester yarns is expected to grow at a higher rate.

Other materials like Rayon, despite its superior properties, have lost its use to due to higher cost of production in radial tires compared to competing materials like polyester. With weight reduction as the aim, aramid fiber yarn is set to replace steel as belt reinforcement material in tires.

Revival From the Current Slowdown Imperative for Growth

There has been weaker than anticipated global activity in the first quarter of 2019 and the global growth in 2019 is expected to slow down to 2.6% and is expected to rise gradually in 2020. The manufacturing sector has been the most hit by this due to weakening consumer demand. According to the report from Germany’s Centre for Automotive Research (CAR), the world car sales is expected to fall by 4 million and would only recover by 2022. Further the stringent emission norms, the US trade sanctions and the ensuing US-China trade war will have a significant impact on the tire yarn market demand. The pace of revival will be key to market growth.