According to estimates from Stratview Research, the global cold plasma market reached annual sales exceeding US$ 1.6 billion in 2019, achieving a strong double-digit growth rate over the previous five years after evaluating key drivers, restraints, and industry dynamics.

Aurora or the Northern lights, the magnificent green hue that appears in the sky near Arctic and Antarctic regions has been a subject of much poetry and occult. Scientifically it is “Plasma”, one of the four fundamental states of matter that causes the fluorescent green colour. It is ironic because the word plasma engenders an image of hot gas, with its constituents in an ionic state, but apparently, there are two types of plasma, Hot and Cold. Of them, only Cold PLasma is of human use.

The genesis of cold plasma can be traced to 1960s when cold Plasma was used for sterilization and was found highly effective. Though its applications have picked up recently, and within a short span of time cold plasma technology has found commercially successful applications in many industries.

Electricals & Electronics, Food, Medical, Textile, Polymers & Plastics, are the major end-user industries (in decreasing order of market share). Other end-user industries including Building, Construction, Sports, Consumer Goods, Automotive etc. have successfully inculcated Cold Plasma technology.

Cold Plasma is essentially a disruptive technology as its applications harbour a radically different approach. In the majority of viable applications, Cold Plasma has been found to be superior to conventional approaches; in the medical field the sterilization, bio-film removal, bleaching efficacy, cancer treatment and in the surface treatment of polymers etc., cold plasma has delivered better results.

Also, cold plasma offers numerous benefits over its competing technologies like cost savings, a greater energy efficiency, shorter processing time and eco-friendliness. Furthermore, the process is dry and clean, abrogating the use of a high amount of chemicals.

Cold Plasma Market: An Ocean of Growth Opportunities

As estimated by Stratview Research, after analyzing a whole host of factors, growth drivers and constraints, the global cold plasma market clocked an annual sales of over $1.6 billion in 2019 registering a double digit growth rate over the past five years.

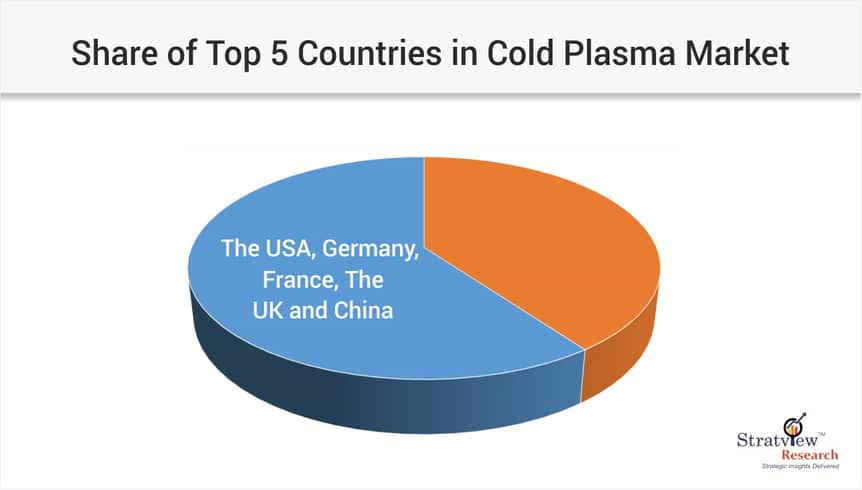

Europe and North America, the pioneers and early adopters of most of the innovative technologies are also the dominating ones in cold plasma technology and together account for three-fourths of the global market. The top five major countries, the USA, Germany, France, the UK and China, together account for two-thirds of global cold plasma market in 2019 and are poised to remain so.

Figure : Global Cold Plasma Market: Contribution of the Top 5 Countries

The highly fragmented global cold plasma market has Nordson Corporation, Plasmatreat GmbH, Adtec Plasma Technology Co. Ltd., P2i Limited, and Enercon Industries Corporation, at the helm and together they accounted for less than one-fourth of the total market.

Cold Plasma can be used in either Low-pressure or Atmospheric-pressure modes. Currently low-pressure dominates the market, though easy to use atmospheric-pressure applications are growing faster, albeit marginally.

Cold plasma has found copious applications in varied domains such as cleaning & activation, coating, decontamination, wound healing, adhesion, finishing, sterilization (in decreasing order of market share). Other applications include etching, printing, bleaching & dying, blood coagulation, surgical, polymerization and odour control.

Cleaning & activation applications are projected to remain the largest application with a double-digit CAGR during the forecast period, driven by the demand in E&E, polymers, plastics and medical end-use industries, while decontamination is expected to have the highest growth among all the applications.

Electricals & Electronics is the largest end-user industry with around a third of the market share. Cold plasma technology provides uniform coverage over the three-dimensional body as the gases like Helium, Argon and Oxygen (in the plasma state) are directed over the surface via a nozzle. Very thin coating over the devices and delicate parts of the microelectronics is done effectively.

The Food industry is the second largest end-user industry. The new horizons of application in the food industry have propelled the food industry to achieve the highest growth, in double-digits. Delivering cost reduction, longer shelf-life and low level of pathogens, have been the key factors behind its growth. The technology outperforms competing technologies, such as X-Ray, pulsed light, ultraviolet (UV) light, e-beam, and high-pressure processing (HPP).

In the food industry, decontamination and wound healing are set to register the highest growth of over double digits.

In the medical industry, it provides safe and effective surgical procedures for controlled cutting, coagulation of blood and ablation of tissues with minimum thermal spread to adjacent tissues.

In the textile industry, this technology is applicable to almost all organic, organo-metallic, and heteroatomic organic components. It modifies surface properties without changing bulk properties and is safe for humans.

Growth Factors

Cold Plasma is catapulted into the higher growth spectrum by two factors; the relative advantages on cold plasma technology in almost all the spheres of application and new applications of the technology. Below are a few examples of recent applications:

- It can cause chronic wounds to close up within just a few weeks. In 2018, scientists from Greifswald in Germany have developed a new wound dressing based on WACKER silicones that creates high-energy gas directly on the damaged skin.

- In 2018, atmospheric cold plasma was used to effectively reduce pathogens on apples, with reference to Salmonella and E. coli.

- In 2018, in the most recent and encouraging finding, researchers have found that Cold Plasma is effective as a new organ-preserving technique (discovered while performing partial splenectomy) and has high efficiency during surgical interventions. In time its suitability as a surgical aid will become more clear.

- Cold plasma skin welding is a novel technology (2016) that bonds skin edges through soldering without the use of synthetic materials or conventional wound approximation methods such as sutures, staples, or skin adhesives.

Such new applications of Cold Plasma (CP) will keep the growth momentum strong.

The need for high-quality products is also pushing the adaptation of Cold Plasma, especially in E&E industry. The cold plasma technology has gained the industry stakeholder’s confidence with its high-quality results.

The rise in the usage of advanced technology in various end-use industries intended to cut downtime, effort and cost with the desired rise in quality of products is boosting the adaptation of Cold Plasma.

Environment first, is the contemporary moto of all the economies. Many of existing cleaning processes used today involve the use of solvents and aqueous systems with having many disadvantages. They engage larger space, higher cost of energy used and disposal cost of bi-products, along with higher VOC emissions & usage of scarce water. Cold plasma is a safer, eco-friendly and more effective than the traditional wet-chemical procedure in removing highly stubborn contaminants, such as large particles and thick layers. A leading manufacturer has explained that we can save approximately 115 liters of water, 80 kg of carbon dioxide and 5 kg of coating-chemicals by using 1 kg of their cold plasma product. With its minimal environmental footprint and fractional use of resources, Cold Plasma provides many inducements for its use.

Skilled Workforce Bottleneck & The Road Ahead

Cold Plasma technology entails the use of highly skilled workforce as technology delivers high precision (ex. Surgeries, fluid control), time exactitude (material treatment) and gingerly inspection of product pre & post treatment, necessitates the employment of highly skilled workforce.

Research on the effects of Cold Plasma is still at a nascent stage, especially in the food processing industry. There are studies going on over the unexplored impacts of cold plasma treatment on the sensory and nutritional values of the food. Due to the non-thermal nature, CP treatments have shown no or minimal impact on the physical, chemical, nutritional and sensory attributes of various products, some studies have concluded. A study which analysed the after effect of treating oral cancer with cold atmospheric plasma (CAP) and have found it to have no major negative effects. So far, no major drawback of cold Plasma has been found.

With a multitude of advantages in diverse industries, cold plasma is set to grow bigger. In the wake of the COVID-19 outbreak, the technology may witness an upsurge in applications including cleaning & activation, decontamination, and sterilization. As new boulevards of applications being discovered frequently and the penetration in the present end-user industries deepen, the growth should continue unabated.