Stratview Research states that demand for automotive composites is rising, with RV composites growing faster at a 7% CAGR. Outdoor recreation is booming, as camping has surged 64% since 2014, driven largely by Gen-X and millennial campers.

When we talk about Recreational Vehicles (RV), optimum utilisation of space is an operative word, with spacious interiors and dynamic layouts being the need of the hour. Another factor that adds to the efficiency of the vehicle, is maintaining an overall lower weight. The impetus to produce light weight vehicles is that manufacturers can add other luxurious comforts to the vehicle without impacting overall weight. This helps in easy towing of the vehicle without the need of a vehicle with greater towing capacity.

Composites play an important role in achieving these standards. RV manufactures have been experimenting different composite materials, doing away with the traditional steel, aluminium and plywood, increasing the demand for composites in the RV manufacturing.

The RVs are either towable or motorised vehicles. The towable RVs like trailers and truck campers are designed to be pulled by a motorised vehicle and can be unhooked from the tow vehicle. The motorised RVs called motorhomes, are self- propelled, including transportation and living quarters in one.

Increasing Penetration of Composites in the Rv Segment

The demand for composites in the automotive industry is snowballing. The Recreational Vehicles industry represents 1.5% of the automotive composites market, but it is witnessing a higher growth than the average automotive composites market growth. The RV composite panel market is set to grow at a CAGR of 7% over the next five years due to organic growth in Recreational Vehicles.

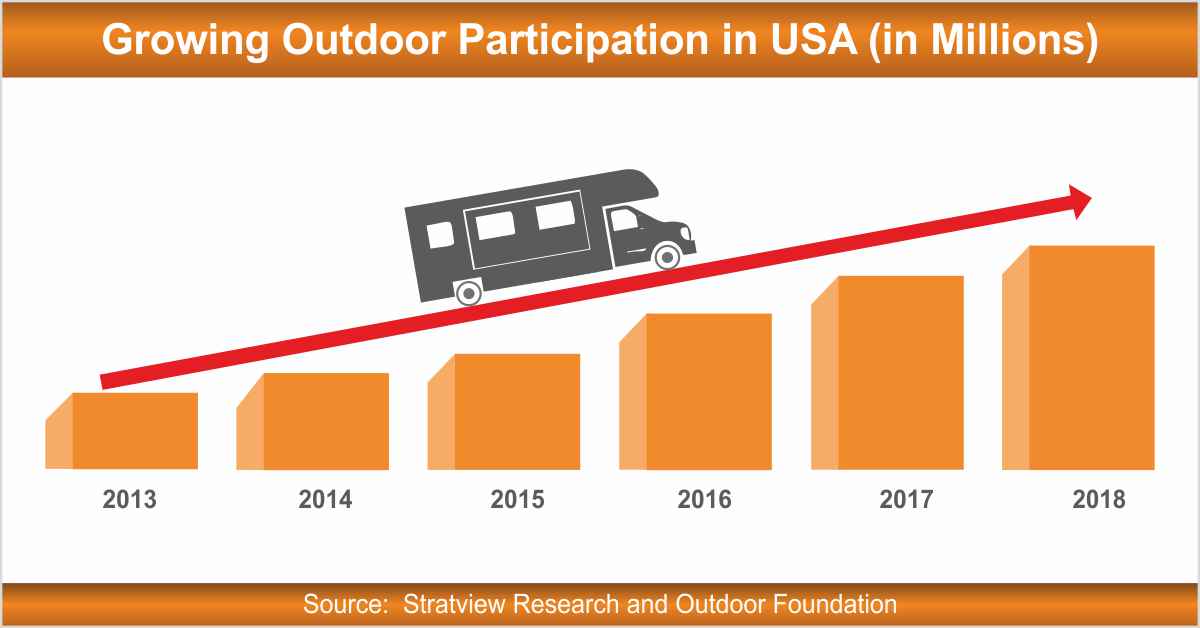

Outdoor activities have ruled recreational activities in the west. Camping as an outdoor activity, with campers taking 3 or more trips in a year, has increased by 64% since 2014. The Gen – X (ages 35-54) and millennials (ages 18-35) are driving the growth, making up to 76% of the new campers in 2018.

Figure: Outdoor Recreation Participation Trend in the USA

Reaping the Benefits of Composites Panels

RV’s are parked outside in all types of weather, exposing them to direct UV rays and even rains. Wooden products, used in sidewalls and floor panels are prone to swelling from moisture intrusion. Composites not only provide the benefit of weight reduction, but also high level of design flexibility, durability, high impact strength, resistance to Ultraviolet light, superior strength to weight ratio, thermal insulation and corrosion resistance.

The composite panels are mainly used in the sidewall panels, roof panel, floor panel and slide out panel. The sidewall panels are the main structure of the RV and account for a major share of the RV composite panels market. Roof composite panels are seamlessly attached to the side walls, making a no leak roof system. The floor panel is thicker than the roof panel due to high tolerance and strength requirements. The floor composite panels are the fastest growing segment witnessing a CAGR of 7.7%.

All the major panels are mainly made of Polyester resins with glass fiber through the continuous lamination process. They offer better water resistance, weatherability and most important, low cost as compared to their counterparts. Other resins used are epoxy, vinyl ester and polypropylene. Epoxy resins are costly and mainly used in floor and roof applications.

Composite panels are made by sandwiching a core material between the fibre reinforced laminates. The core materials used are PS Foam, PU Foam, balsa, PET and honeycomb. Most of the panels are made using PS foam.

PS foams have the inherent property of absorbing very little water in wet conditions due to its closed cells structure, leading to better thermal conductivity compared to PU foam and other competing materials, making them the first choice of panel manufacturers. Dow Chemicals is the leading and practically the only PS foam supplier in the market, with others having negligible share in the supply.

North America Leading the Sales

North America has been driving the growth of RV Composite Panels, as the USA has the highest participation in outdoor activities compared to the emerging economies and rest of the world. The constraint of open camping spaces is also being addressed by the government by creating more camping infrastructure. Europe comes second in terms of RV sales. However, towable RVs are more common in the USA, as they have better camping infrastructure. Also, towable RVs offer better space and an option of a sliding panel.

Motorised RVs, being compact, rule the European market as the ancient cities of Europe have narrow lanes and large camping spaces are not easily available.

Crane Composites is one of the leading suppliers in North America along with other top players concentrated in this region due to high demand from USA. Lamilux Composites rules the European Market.

Economic Growth, the Mainstay

For any recreational industry, booming economy and rising per capita income is the key to driving demand and growth. The global economy is undergoing a downward phase which is expected to turnaround by the year 2021. Apart from this, the high cost of the composite panels as compared to traditional one, drive up the cost of manufacturing, which is eventually passed on to the consumers. However, the consumers’ need for aesthetics and low maintenance counters this. Another concern is the availability of safe and secure camping infrastructure. The governments of the developed nations and to some extent emerging economies are addressing this issue by creating more camping spaces. Overall, this augurs well for the RV Composite Panels market.