Market Insights

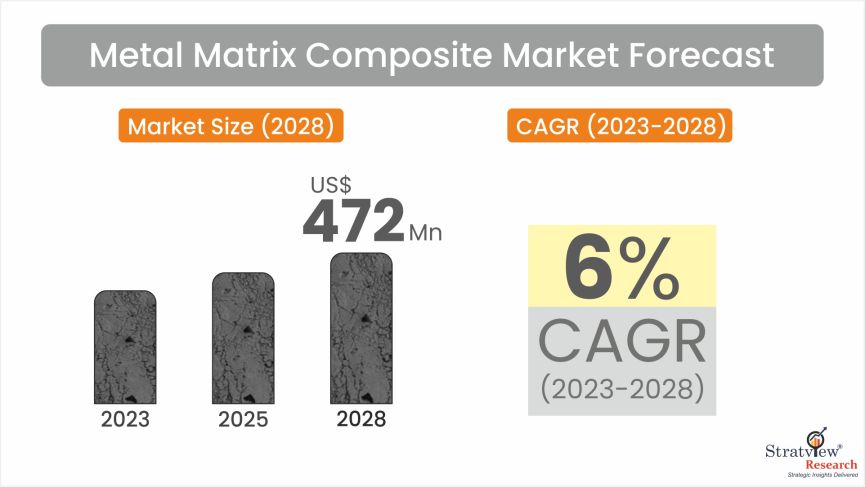

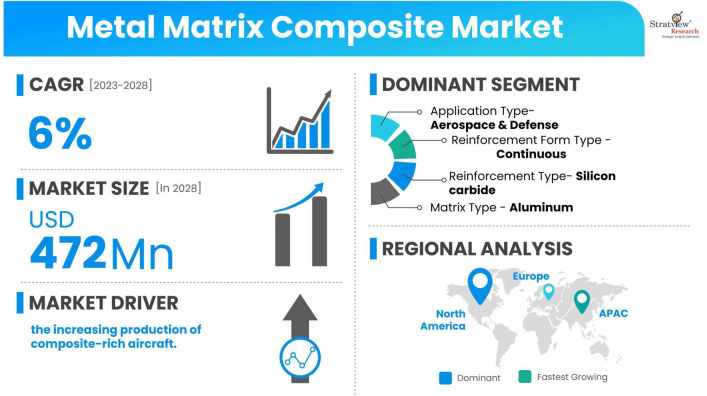

“The metal matrix composite market is likely to grow at a promising CAGR of 6% during 2023-2028 to reach USD 472 million in 2028.”

Want to know more about the market scope? Register Here

Market Dynamics

Introduction

Metal matrix composite (MMC) is a type of advanced material that consists of a metal matrix (such as aluminum or titanium) reinforced with particles, fibers, or whiskers to create a composite material with enhanced properties. It combines metals' strength and flexibility with reinforcing materials' stiffness and wear resistance, resulting in composites with improved mechanical, thermal, and electrical properties.

Due to these properties, MMC has various applications in different industries, including aerospace and defense, transportation (automotive and rail), energy, oil and gas, and electronics.

COVID-19 Impact

The COVID-19 pandemic had a pervasive impact on various industries, including aerospace & defense, automotive, energy, and electronics. The aerospace & defense industry felt the most substantial influence as the pandemic led to a sharp decline in air travel, reducing demand for new aircraft, and high-performance structural materials like MMCs. Hence, the metal matrix composites market experienced a substantial downturn (15%+) in 2020.

Market Drivers

The increase in the adoption of MMCs in various applications across different industries, the increasing production of composite-rich aircraft, the growing utilization of metal matrix composites in the space industry, and numerous advantages of MMCs, such as a high strength-to-weight ratio, excellent corrosion resistance, excellent fatigue strength, lightweight, and excellent durability, are key factors collectively driving market growth.

Moreover, MMC's substantial usage in electronic packaging, primarily for effective heat management in electronic devices, is complemented by its increasing adoption in semiconductor applications. This expansion is a significant catalyst for the market's growth in the coming years.

Want to have a closer look at this market report? Click Here

Key Players

The market is moderately populated, with the presence of some regional and global players. Most of the major players compete on some of the governing factors, including price, product offerings, regional presence, etc.

The following are the key players in the metal matrix composite market (arranged alphabetically).

- AMETEK, Inc.

- CPS Technologies Corporation

- Denka Company Ltd.

- Deutsche Edelstahlwerke (part of the Swiss Steel Group)

- Ferrotec

- Materion Corporation

- Plansee SE

Note: The above list does not necessarily include all the top players in the market.

Are you the leading player in this market? We would love to include your name. Write to us at sales@stratviewresearch.com

Segments Analysis

|

Segmentations

|

List of Sub-Segments

|

Dominant and Fastest-Growing Segments

|

|

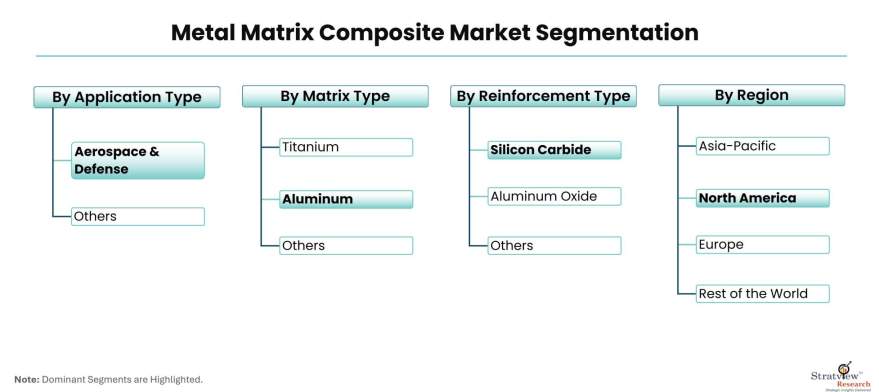

Application Type

|

Aerospace & Defense and Others

|

Aerospace and defense are the biggest markets for MMCs and will maintain their position in the coming years too.

|

|

Matrix Type

|

Aluminum, Titanium, and Others

|

Aluminum holds a predominant position as the primary matrix in the market.

|

|

Reinforcement Type

|

Silicon Carbide, Aluminum Oxide, and Others

|

Silicon Carbide maintains a leading role as the primary reinforcement in the market.

|

|

Reinforcement Form Type

|

Continuous, Discontinuous, and Particulate

|

Continuous stands out as the prevailing reinforcement form in the market.

|

|

Process Type

|

Solid State Processing, Liquid State Processing, and Others

|

Solid-state processing is expected to remain the most preferred process in the market.

|

|

Regional Analysis

|

North America, Europe, Asia Pacific, and The Rest of the World

|

North America is expected to remain the dominant market over the next five years, whereas Asia-Pacific is likely to grow at the fastest rate.

|

By Application Type

“Aerospace & Defense dominates the market during the forecast period.”

The metal matrix composites market is segmented into aerospace & defense and others. Aerospace & Defense is projected to maintain its dominant position in the market during the forecast period. An increase in the production rate of composite-rich aircraft programs, growing demand for lightweight yet durable parts, the advantages of MMC (Metal Matrix Composites), such as their high strength-to-weight ratio, durability, and corrosion resistance, making them ideal for lightweight structural components in aircraft and spacecraft, and the expanding utilization of MMCs in defense applications, including armor, are expected to be significant growth drivers of the market.

Other key applications of MMCs include electronic devices, semiconductors, engine components, brake systems, and suspension parts (in automotive).

By Matrix Type

“Aluminum dominates the market during the forecast period.”

The market is segmented into aluminum, titanium, and others. Aluminum is expected to persist as the foremost matrix type in the market during the forecast period due to its low weight and cost-effectiveness properties.

Titanium is expected to remain the fastest-growing matrix type in the market during the forecast period owing to its numerous advantages, such as a high-strength-to-weight ratio, high tensile and compressive strength, a low coefficient of thermal expansion, and high fatigue resistance.

Want to get more details about the segmentations? Register Here

By Reinforcement Type

“Silicon carbide dominates the market during the forecast period.”

The market is segmented into silicon carbide, aluminum oxide, and others. Silicon carbide is poised to uphold its prominent status as the dominant reinforcement type in the market during the forecast period owing to its lightweight, high strength and stiffness, high-temperature resistance, abrasion, fatigue, and corrosion resistance properties.

By Reinforcement Form Type

“Continuous reinforcement dominates the market during the forecast period.”

The market is segmented into continuous, discontinuous, and particulate. Continuous reinforcement is projected to remain dominant in the market during the forecast period, as it provides a high level of strength and stiffness to the composite material, which is crucial for structural components in aircraft and other applications that need to withstand high loads and stresses.

Regional Insights

“North America is expected to remain the dominant market for metal matrix composites during the forecast period.”

The USA is likely to remain the growth engine of the region’s market as it is the manufacturing hub of the aerospace industry, along with the presence of key MMC manufacturers, tier players, OEMs, and other industry players.

Asia-Pacific is estimated to remain the fastest-growing market for metal matrix composites in the foreseeable future. Increasing investment in various industries, including aerospace, automotive, electronics, and energy, and the growing adoption of advanced technologies are key factors driving the region’s market.

Know the high-growth countries in this report. Register Here

Research Methodology

This strategic assessment report, from Stratview Research, provides a comprehensive analysis that reflects today’s metal matrix composite market realities and future market possibilities for the forecast period. The report segments and analyzes the market in the most detailed manner to provide a panoramic view of the market. The vital data/information provided in the report can play a crucial role for market participants as well as investors in the identification of the low-hanging fruits available in the market as well as formulate growth strategies to expedite their growth process.

This report offers high-quality insights and is the outcome of a detailed research methodology comprising extensive secondary research, rigorous primary interviews with industry stakeholders, and validation and triangulation with Stratview Research’s internal database and statistical tools.

More than 1,000 authenticated secondary sources, such as company annual reports, fact books, press releases, journals, investor presentations, white papers, patents, and articles, have been leveraged to gather the data. We conducted more than 15 detailed primary interviews with market players across the value chain in all four regions and industry experts to obtain both qualitative and quantitative insights.

Report Features

This report provides market intelligence in the most comprehensive way. The report structure has been kept such that it offers maximum business value. It provides critical insights into market dynamics and will enable strategic decision-making for existing market players as well as those willing to enter the market. The following are the key features of the report:

- Market structure: Overview, industry life cycle analysis, supply chain analysis.

- Market environment analysis: Growth drivers and constraints, Porter’s five forces analysis, SWOT analysis.

- Market trend and forecast analysis.

- Market segment trend and forecast.

- Competitive landscape and dynamics: Market share, Service portfolio, New Product Launches, etc.

- COVID-19 impact and its recovery curve

- Attractive market segments and associated growth opportunities.

- Emerging trends.

- Strategic growth opportunities for the existing and new players.

- Key success factors.

Market Segmentation

This report studies the market, covering a period of 12 years of trend and forecast. The report provides detailed insights into the market dynamics to enable informed business decision-making and growth strategy formulation based on the opportunities present in the market.

The metal matrix composite market is segmented into the following categories:

By Application Type

- Aerospace and defense

- Others

By Matrix Type

- Aluminium

- Titanium

- Others

By Reinforcement Type

- Silicon Carbide

- Aluminium Oxide

- Others

By Reinforcement Form Type

- Continuous

- Discontinuous

- Particulate

By Process Type

- Solid State Processing

- Liquid State Processing

- Others

By Region

- North America (Country Analysis: the USA, Canada, and Mexico)

- Europe (Country Analysis: Germany, France, the UK, Russia, Spain, and Rest of Europe)

- Asia-Pacific (Country Analysis: China, Japan, India, South Korea, and Rest of Asia-Pacific)

- Rest of the World (Sub-Region Analysis: Latin America, the Middle East, and Others)

Click here to learn the market segmentation details.

Report Customization Options

With this detailed report, Stratview Research offers one of the following free customization options to our respectable clients:

Company Profiling

- Detailed profiling of additional market players (up to three players)

- SWOT analysis of key players (up to three players)

Competitive Benchmarking

- Benchmarking of key players on the following parameters: Product portfolio, geographical reach, regional presence, and strategic alliances

Custom Research: Stratview Research offers custom research services across sectors. In case of any custom research requirement related to market assessment, competitive benchmarking, sourcing and procurement, target screening, and others, please send your inquiry to sales@stratviewresearch.com

Recent Market News

-

In March 2021, Alvant, a prominent expert in the production of metal matrix composite (MMC) materials, entered into a Memorandum of Understanding (MoU) aimed at advancing a strategic partnership with the advanced materials technology firm 3M. This collaboration is intended to expedite the enhancement of Alvant's capabilities and the discovery of practical applications in real-world scenarios.