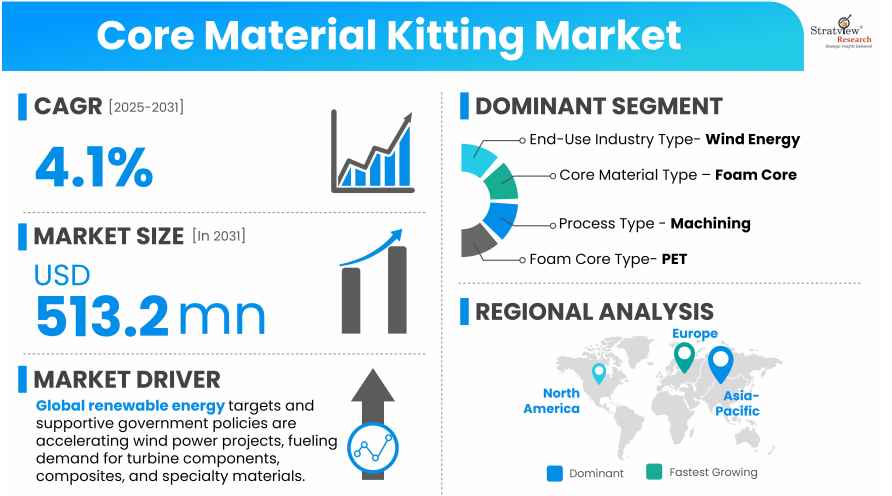

“The core material kitting market was valued at US$ 384.8 million in 2024 and is likely to grow at a CAGR of 4.1% in the long run to reach US$ 513.2 million in 2031.”

Want to get a free sample? Register Here

Market Dynamics

Introduction

Core material kitting is the process of cutting the core material into desired shapes of components, flattening surfaces, digitizing data, developing the kit, managing the material supply, and organizing the kit to save time and money, resulting in more productivity and profitability. Core material kitting offers faster and easier dry layup in molds, ease in assembly, an exact fit, and minimum waste. It eliminates on-site shaping and cutting, reduces build times, and saves labor and material costs with consistently high quality in less time. The kitting of core materials can be performed by part fabricators in-house and outsourced to independent kitting solution providers or core material suppliers that also offer kitting services.

The market drivers include:

- Expected Rise in Wind Turbine Installations: Global renewable energy targets and supportive government policies are accelerating wind power projects, fueling demand for turbine components, composites, and specialty materials.

- Expected Increase in Aircraft Fleets: Growing air travel demand and fleet modernization programs are driving increased procurement of fuel-efficient, next-generation aircraft by both commercial and defense sectors.

- Expected Recovery in Automotive Production: Easing supply chain constraints and rising EV adoption are expected to boost global automotive output, supporting upstream demand for components, materials, and electronics.

Segments Analysis

|

Segmentations

|

List of Sub-Segments

|

Segments with High Growth Opportunity

|

|

End-Use Industry Type

|

Wind Energy, Aerospace & Defense, Marine, Transportation, Construction, and Other End-Use Industries.

|

Wind energy is expected to remain the largest market for core material kitting during the forecast period due to rising demand for an alternative source of energy.

|

|

Core Material Type

|

Foam Core and Balsa

|

Foam core is expected to remain dominant in the market by 2031, owing to its wide usage in wind energy and marine composite parts.

|

|

Foam Core Type

|

PVC Foam Core, PET Foam Core, and Other Foam Cores

|

PET to remain the dominant foam core type over the coming years due to wider acceptance in wind energy, marine, and aerospace & defense.

|

|

Process Type

|

Machining and Manual

|

Machining process to remain dominant in the market during the forecast period.

|

|

Region Analysis

|

North America, Europe, Asia-Pacific, and The Rest of the World

|

Asia-Pacific is expected to remain the largest market for structural core materials during the forecast period.

|

By End-Use Industry Type

“Wind energy is expected to remain the biggest demand generator of the core materials market during the forecast period.”

The market is segmented into wind energy, aerospace & defense, marine, transportation, construction, and other end-use industries. Wind energy is expected to remain the largest market for core material kitting during the forecast period. Rising demand for an alternative source of energy has led to an increased focus by various governments and non-government institutions on the wind energy industry.

Increasing wind turbine installation coupled with the installation of longer rotor blades has resulted in a greater penetration of sandwich panels constructed with foam and balsa core materials. This factor is acting as the prime driver for the core material kitting market in wind energy.

By Core Material Type

“Foam core type to grow over the coming years due to wider acceptance in wind energy, marine, and aerospace & defense.”

Based on the core material type, the market is segmented as foam core and balsa. Foam core is further bifurcated into PVC, PET, and others. Foam core is expected to remain the market’s larger category during the forecast period. Foam core is widely used in wind energy and marine composite parts, owing to its low specific weight and high mechanical rigidity and stiffness.

Regional Analysis

“Asia-Pacific will continue as the largest market for structural core materials, with Europe as the second-largest during the forecast period.”

The growth engine of Asia-Pacific is mainly attributable to the large wind turbine installation coupled with the regional expansion of major core material suppliers in the region; the growing penetration of composites in the transportation industry; the opening of assembly plants of Boeing and Airbus for the B737, A320, and A330 aircraft programs; indigenous aircraft programs such as the C919; and the expanding construction industry.

Europe is expected to be the fastest-growing market for core material kitting during the forecast period, owing to an expected increase in offshore wind turbine installations in Europe and a healthy recovery in the aerospace & defense industry.

Want to get a free sample? Register Here

Key Players

The market is highly consolidated with the presence of some regional and global players. The supply chain of the market comprises raw material suppliers, core material suppliers, tier players, and end-users.

.Here is the list of the Top Players (Based on Alphabetical Order)

- 3A Composites GmbH

- Diab International AB

- Gurit Holding AG

- InCom Group

Note: The above list does not necessarily include all the top players in the market.

Are you the leading player in this market? We would love to include your name. Please write to us at [email protected]

Report Features

This report provides market intelligence most comprehensively. The report structure has been kept so that it offers maximum business value. It provides critical insights into market dynamics and will enable strategic decision-making for existing market players as well as those willing to enter the market. The following are the key features of the report:

- Market structure: Overview, industry life cycle analysis, supply chain analysis.

- Market environment analysis: Growth drivers and constraints, Porter’s five forces analysis, SWOT analysis.

- Market trend and forecast analysis.

- Market segment trend and forecast.

- Competitive landscape and dynamics: Market share, Service portfolio, New Product Launches, etc.

- COVID-19 impact and its recovery curve.

- Attractive market segments and associated growth opportunities.

- Emerging trends.

- Strategic growth opportunities for the existing and new players.

- Key success factors.

The global core material kitting market is segmented into the following categories.

Core Material Kitting Market, by End-Use Industry

- Wind Energy (Regional Analysis: North America, Europe, Asia-Pacific, and Rest of the World)

- Marine (Regional Analysis: North America, Europe, Asia-Pacific, and Rest of the World)

- Ground Transportation (Regional Analysis: North America, Europe, Asia-Pacific, and Rest of the World)

- Aerospace & Defense (Regional Analysis: North America, Europe, Asia-Pacific, and Rest of the World)

- Other End-Use Industries (Regional Analysis: North America, Europe, Asia-Pacific, and Rest of the World)

Core Material Kitting Market, by Core Material

- Foam Core (Regional Analysis: North America, Europe, Asia-Pacific, and Rest of the World)

- Balsa (Regional Analysis: North America, Europe, Asia-Pacific, and Rest of the World)

Core Material Kitting Market, by Foam Core

- PVC (Regional Analysis: North America, Europe, Asia-Pacific, and Rest of the World)

- PET (Regional Analysis: North America, Europe, Asia-Pacific, and Rest of the World)

- SAN (Regional Analysis: North America, Europe, Asia-Pacific, and Rest of the World)

- PMI (Regional Analysis: North America, Europe, Asia-Pacific, and Rest of the World)

- Other foam cores (Regional Analysis: North America, Europe, Asia-Pacific, and Rest of the World)

Core Material Kitting Market, by Region

- North America (Country Analysis: The USA, Canada, and Mexico)

- Europe (Country Analysis: Germany, France, The UK, Russia, and the Rest of Europe)

- Asia-Pacific (Country Analysis: Japan, China, India, and Rest of Asia-Pacific)

- Rest of the World (Country Analysis: Middle East, Latin America, and Others)

Research Methodology

- This strategic assessment report from Stratview Research provides a comprehensive analysis that reflects today’s core material kitting market realities and future market possibilities for the forecast period.

- The report segments and analyzes the market in the most detailed manner to provide a panoramic view of the market.

- The vital data/information provided in the report can play a crucial role for market participants and investors in identifying the low-hanging fruit available in the market and formulating growth strategies to expedite their growth process.

- This report offers high-quality insights and is the outcome of a detailed research methodology comprising extensive secondary research, rigorous primary interviews with industry stakeholders, and validation and triangulation with Stratview Research’s internal database and statistical tools.

- More than 1,000 authenticated secondary sources, such as company annual reports, fact books, press releases, journals, investor presentations, white papers, patents, and articles, have been leveraged to gather the data.

- We conducted more than 10 detailed primary interviews with market players across the value chain in all four regions and industry experts to obtain both qualitative and quantitative insights.

Customization Option

With this detailed report, Stratview Research offers one of the following free customization options to our respected clients:

Company Profiling

- Detailed profiling of additional market players (up to three players)

- SWOT analysis of key players (up to three players)

Competitive Benchmarking

- Benchmarking of key players on the following parameters: Service portfolio, geographical reach, regional presence, and strategic alliances

Custom Research: Stratview Research offers custom research services across sectors. In case of any custom research requirement related to market assessment, competitive benchmarking, sourcing and procurement, target screening, and others, please send your inquiry to [email protected]