Attractive Opportunities

Global Demand Analysis & Sales Opportunities in Hydrogen Seals Market

-

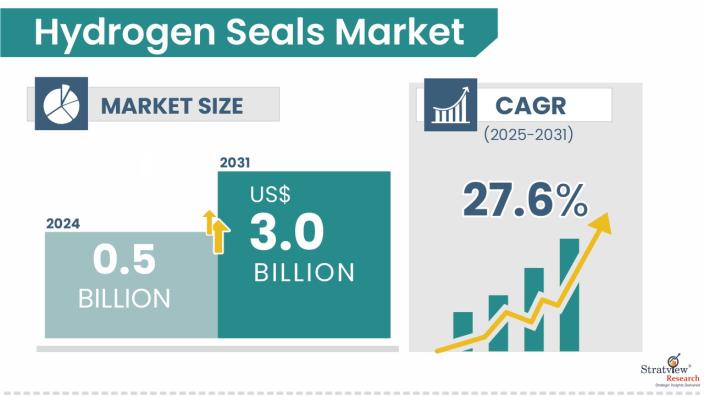

The annual demand for hydrogen seals was USD 497.4 million in 2024 and is expected to reach USD 685.7 million in 2025, up 37.9% than the value in 2024.

-

During the forecast period (2025-2031), the hydrogen seals market is expected to grow at a CAGR of 27.6%. The annual demand will reach USD 2964.4 million in 2031, which is almost 4 times the demand in 2025.

-

During 2025-2031, the hydrogen seals industry is expected to generate a cumulative sales opportunity of USD 11604.8 million, which is more than 2 times the opportunities during 2019-2024.

Want to know more about the market scope? Register Here

High-Growth Market Segments:

-

Asia-Pacific generated the highest demand with the largest market share of more than 65% in 2024.

-

By application type, Compressor is expected to be the biggest demand generator for hydrogen seals during the forecast period.

-

By seal type, Mechanical seals are anticipated to be the most demanding seal type during the forecast period.

-

By motion type, Rotary seals are estimated to hold the major share of the market during the forecast period.

-

By material type, Metallic seals are likely to be the market's most preferred choice during the forecast period.

Market Statistics

Have a look at the sales opportunities presented by the hydrogen seals market in terms of growth and market forecast.

|

Hydrogen Seals Market Data & Statistics

|

|

|

Market Statistics

|

Value (in USD Billion)

|

Market Growth (%)

|

|

Annual Market Size in 2023

|

USD 366.2 million

|

-

|

|

Annual Market Size in 2024

|

USD 497.4 million

|

YoY Growth in 2024: 35.8%

|

|

Annual Market Size in 2025

|

USD 685.7 million

|

YoY Growth in 2025: 37.9%

|

|

Annual Market Size in 2031

|

USD 2964.4 million

|

CAGR 2025-2031: 27.6%

|

|

Cumulative Sales Opportunity during 2025-2031

|

USD 11604.8 million

|

-

|

|

Top 10 Countries’ Market Share in 2024

|

USD 397.9 million +

|

> 80%

|

|

Top 10 Company’s Market Share in 2024

|

USD 248.7 million to USD 348.2 million

|

50% - 70%

|

Market Dynamics

Introduction:

What are hydrogen seals?

Hydrogen seals are critical components in the hydrogen economy, ensuring the safe and efficient operation of hydrogen production, storage, distribution, and utilization systems. These seals are designed to withstand the unique challenges posed by hydrogen, including its small molecular size, high diffusivity, and propensity to cause material embrittlement. They play a crucial role in preventing leaks, maintaining system integrity, and ensuring safety across various applications, including fuel cells, electrolysers, valves, tanks, compressors, and hydrogen refuelling stations.

Market Drivers:

-

The hydrogen seals market is experiencing significant growth, driven by the global shift towards sustainable energy solutions and the increasing adoption of hydrogen as a clean energy carrier.

-

As governments and industries invest in hydrogen infrastructure to meet decarbonization goals, the demand for advanced sealing technologies has surged. The rise of hydrogen as a cornerstone for decarbonizing industries such as transportation, energy, and manufacturing has amplified the need for seals capable of enduring extreme pressures (up to 700 bar) and cryogenic temperatures (-253°C for liquid hydrogen).

-

Innovations in material science have led to the development of seals capable of withstanding extreme pressures, wide temperature fluctuations, and chemically reactive environments inherent in hydrogen applications. Ongoing R&D efforts to improve cost-efficiency, scalability, and material resilience are expected to drive market expansion, aligning with global net-zero targets and the escalating demand for hydrogen as a clean energy vector.

Segments Analysis

|

Segmentations

|

List of Sub-Segments

|

Segments with High-Growth Opportunity

|

|

Application-Type Analysis

|

Electrolyzer, Valve, Fuel Cell, Composite Tank, Compressor, and Refuelling Connectors/Nozzles

|

The compressor is expected to be the biggest demand generator for hydrogen seals during the forecast period.

|

|

Seal-Type Analysis

|

O-rings, Gaskets, Energized Seals, Lip Seals, Mechanical Seals, and Seals.

|

Mechanical seals are anticipated to be the most demanding seal type during the forecast period.

|

|

Motion-Type Analysis

|

Static Seals, Linear Seals, and Rotary Seals.

|

Rotary seals are estimated to hold the major share of the market during the forecast period.

|

|

Material-Type Analysis

|

Elastomeric Seals, Thermoplastic Seals, and Metallic Seals.

|

Metallic seals are likely to be the market's most preferred choice by material type during the forecast period.

|

|

Regional Analysis

|

North America, Europe, Asia-Pacific, and The Rest of the World

|

Asia-Pacific is expected to maintain its reign over the forecast period.

|

By Application Type

“Compressor is expected to maintain a leading market share throughout the forecast period.”

-

The market is segmented into electrolyzers, valves, fuel cells, composite tanks, compressors, and refueling connectors/nozzles, with compressors expected to dominate the market during the forecast period.

-

In the hydrogen seals market, the compressor application is expected to be one of the dominant segments due to the critical role compressors play in hydrogen production, storage, and distribution.

-

Compressors are essential for increasing the pressure of hydrogen gas to facilitate its efficient transportation and utilization in various downstream applications, including fuel cell vehicles, industrial processes, and hydrogen refueling stations. The sealing requirements for hydrogen compressors are stringent, as they must prevent gas leakage, ensure operational safety, and withstand extreme pressure and temperature conditions.

-

One of the primary reasons for the dominance of the compressor segment in the hydrogen seals market is the increasing deployment of hydrogen refueling stations (HRS) worldwide. Hydrogen gas needs to be compressed to very high pressures, typically around 350 to 700 bar, before being dispensed into fuel cell vehicles.

By Seal Type

“Mechanical seals are expected to continue as the dominant seal type in the market, as O-rings are likely to be the fastest-growing seal type during the forecast period.”

-

The market is segmented into O-rings, gaskets, energized seals, lip seals, and mechanical seals. Among these, mechanical seals are expected to be the seal type during the forecast period.

-

Mechanical seals play a crucial role in preventing hydrogen leakage in high-pressure and high-temperature environments, particularly in applications such as hydrogen fuel cells, hydrogen storage, and transportation. Their superior durability, reliability, and ability to withstand extreme operating conditions make them the preferred choice for industries adopting hydrogen as an alternative energy source. The increasing deployment of hydrogen infrastructure, particularly in the energy and automotive sectors, further drives the demand for mechanical seals.

-

On the other hand, O-rings are expected to be the fastest-growing seals during the forecast period due to their increasing adoption in fuel cells, electrolyzers, and hydrogen storage systems. O-rings are widely used in static and low-movement sealing applications due to their cost-effectiveness, ease of installation, and reliable sealing performance against hydrogen leakage. The surge in fuel cell vehicle production and green hydrogen initiatives has driven the demand for compact and lightweight sealing solutions, where O-rings serve as an efficient and scalable option.

By Motion Type

“Rotary seals are projected to be the key driver of demand in the hydrogen seals market throughout the forecast period.”

-

The market is segmented into static seals, linear seals, and rotatory seals. The rotary seals segment is expected to be the dominant motion type in the hydrogen seals market throughout the forecast period due to its critical role in compressors, pumps, and rotating equipment used in hydrogen production, storage, and transportation.

-

Rotary seals are designed to withstand high rotational speeds, extreme pressures, and exposure to hydrogen gas, making them essential for ensuring leak-free operation in dynamic sealing applications. Their superior ability to handle friction, wear, and hydrogen permeation makes them a preferred choice for industries that rely on hydrogen compression and transfer systems, such as refueling stations, industrial gas processing, and mobility applications.

-

Additionally, advancements in seal materials and design, such as the use of polytetrafluoroethylene (PTFE) and specialized metal seals, are enhancing the efficiency and durability of rotary seals in hydrogen environments. As industries continue to scale up hydrogen production and distribution infrastructure, the reliance on high-performance rotary seals will only grow, solidifying their position as the dominant motion type in the hydrogen seals market.

By Material Type

“Metallic seals are anticipated to be the preferred material type of the hydrogen seals market throughout the forecast period.”

-

The market is segmented as elastomeric seals, thermoplastic seals, and metallic seals. The metallic seals segment is expected to dominate the hydrogen seals market throughout the forecast period due to its superior performance in high-pressure, high-temperature, and extreme hydrogen environments.

-

Unlike elastomeric and thermoplastic seals, metallic seals provide exceptional hydrogen permeation and embrittlement resistance, making them ideal for applications where safety, reliability, and long-term durability are paramount.

-

Hydrogen, being a small and highly diffusive molecule, can easily penetrate and degrade non-metallic sealing materials over time, leading to leakage and potential system failures.

-

Metallic seals, particularly those made from stainless steel, Inconel, and other advanced alloys, offer enhanced sealing integrity, making them the preferred choice for critical hydrogen applications.

-

One of the primary factors driving the dominance of metallic seals is their extensive use in hydrogen compressors, fuel storage tanks, and refueling systems, where maintaining a secure seal under extreme pressures (up to 700 bar or more) is crucial.

-

Metallic seals are widely employed in hydrogen pipelines, cryogenic storage, and industrial hydrogen processing, where exposure to varying temperatures and harsh operating conditions necessitates robust sealing solutions.

-

The growing deployment of hydrogen refueling stations (HRS) and the expansion of green hydrogen production infrastructure further increase the demand for metallic seals, as these applications require high-performance sealing technologies that can withstand repeated pressure cycles and prolonged exposure to hydrogen gas.

Regional Insights

“The Asia-Pacific region is expected to be the dominant market for hydrogen seals market during the forecast period.”

-

The Asia-Pacific region is expected to dominate the hydrogen seals market throughout the forecast period due to its rapid advancements in hydrogen infrastructure, government initiatives supporting clean energy, and the strong presence of key industrial players investing in hydrogen technologies.

-

Countries such as China, Japan, and South Korea are leading the global hydrogen economy with substantial investments in hydrogen production, storage, and fuel cell technologies, driving the demand for high-performance sealing solutions.

-

The region’s aggressive push toward hydrogen-powered mobility, including fuel cell electric vehicles (FCEVs), buses, and trains, further strengthens the need for reliable hydrogen seals in applications such as fuel cells, refueling stations, and high-pressure storage tanks.

-

China, particularly, heavily invests in green hydrogen production, supported by its national hydrogen strategy and ambitious carbon neutrality goals. The country is rapidly expanding its infrastructure with a growing number of hydrogen refueling stations (HRS), industrial hydrogen projects, and large-scale electrolyzer deployments.

-

Similarly, Japan and South Korea are focusing on hydrogen energy ecosystems, with significant investments in hydrogen-powered transportation, fuel cell technology, and liquid hydrogen storage. These developments require advanced sealing solutions capable of withstanding extreme pressures and temperatures, further boosting the demand for hydrogen seals in the region.

Know the high-growth countries in this report. Register Here

Competitive Landscape

The market is consolidated. The following are the key players in the hydrogen seals market.

Here is the list of the Top Players (Based on Dominance)

Note: The above list does not necessarily include all the top players in the market.

Are you the leading player in this market? We would love to include your name. Please write to us at [email protected]

Report Features

This report provides market intelligence most comprehensively. The report structure has been kept so that it offers maximum business value. It provides critical insights into market dynamics and will enable strategic decision-making for existing market players as well as those willing to enter the market.

The following are the key features of the report:

-

Market structure: Overview, industry life cycle analysis, supply chain analysis.

-

Market environment analysis: Growth drivers and constraints, Porter’s five forces analysis, SWOT analysis.

-

Market trend and forecast analysis.

-

Market segment trend and forecast.

-

Competitive landscape and dynamics: Market share, Service portfolio, New Product Launches, etc.

-

COVID-19 impact and its recovery curve.

-

Attractive market segments and associated growth opportunities.

-

Emerging trends.

-

Strategic growth opportunities for the existing and new players.

-

Key success factors.

|

Market Study Period

|

2019-2031

|

|

Base Year

|

2024

|

|

Forecast Period

|

2025-2031

|

|

Trend Period

|

2019-2023

|

|

Number of Tables & Figures

|

>100

|

|

Number of Segments Analysed

|

5 (Application Type, Seal Type, Motion Type, Material Type, and Region)

|

|

Number of Regions Analysed

|

4 (North America, Europe, Asia-Pacific, Rest of the World)

|

|

Countries Analysed

|

15 (The USA, Canada, Mexico, Germany, France, Italy, The UK, China, Japan, India, Brazil, Saudi Arabia, Rest of Europe, Rest of APAC, and Rest of the World)

|

|

Free Customization Offered

|

10%

|

|

After Sales Support

|

Unlimited

|

|

Report Presentation

|

Complimentary

|

|

Market Dataset

|

Complimentary

|

|

Further Deep Dive & Consulting Services

|

10% Discount

|

Market Segmentation

The report provides detailed insights into the market dynamics to enable informed business decision-making and growth strategy formulation based on the opportunities present in the market.

The hydrogen seals market is segmented into the following categories.

Hydrogen Seals Market, by Application Type

Hydrogen Seals Market, by Seal Type

-

O-rings

-

Gaskets

-

Energized Seals

-

Lip seals

-

Mechanical Seals

-

Others

Hydrogen Seals Market, by Motion Type

-

Static Seals

-

Linear Seals

-

Rotary Seals

Hydrogen Seals Market, by Material Type

-

Elastomeric Seals

-

Thermoplastic Seals

-

Metallic Seals

Hydrogen Seals Market, by Region

-

North America (Country Analysis: The USA, Canada, and Mexico)

-

Europe (Country Analysis: Germany, France, The UK, and Rest of Europe)

-

Asia-Pacific (Country Analysis: China, Japan, India, and Rest of Asia-Pacific)

-

Rest of the World (Country Analysis: Brazil, Saudi Arabia, and Others)

Research Methodology

-

This strategic assessment report from Stratview Research provides a comprehensive analysis that reflects today’s hydrogen seals market realities and future market possibilities for the forecast period.

-

The report segments and analyzes the market in the most detailed manner to provide a panoramic view of the market.

-

The vital data/information provided in the report can play a crucial role for market participants and investors in identifying the low-hanging fruits available in the market and formulating growth strategies to expedite their growth process.

-

This report offers high-quality insights and is the outcome of a detailed research methodology comprising extensive secondary research, rigorous primary interviews with industry stakeholders, and validation and triangulation with Stratview Research’s internal database and statistical tools.

-

More than 1,000 authenticated secondary sources, such as company annual reports, fact books, press releases, journals, investor presentations, white papers, patents, and articles, have been leveraged to gather the data.

-

We conducted more than 15 detailed primary interviews with market players across the value chain in all four regions and industry experts to obtain both qualitative and quantitative insights.

Customization Options

With this detailed report, Stratview Research offers one of the following free customization options to our respectable clients:

Company Profiling

Competitive Benchmarking

-

Benchmarking of key players on the following parameters: Service portfolio, geographical reach, regional presence, and strategic alliances

Custom Research: Stratview Research offers custom research services across industries. In case of any custom research requirement related to market assessment, competitive benchmarking, sourcing and procurement, target screening, and others, please send your inquiry to [email protected]