Market Dynamics

Introduction

Painting robots are robotic systems that are designed to perform the task of painting in industrial applications. These robots are designed with advanced programming and sensors that allow them to complete complex painting tasks with high accuracy and precision. The use of painting robots in industrial settings has numerous benefits, including improved efficiency, higher quality, and reduced costs.

Market Drivers

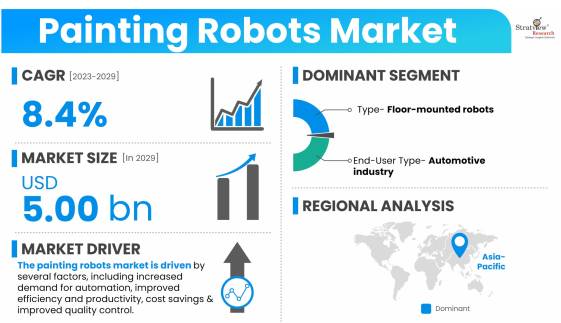

- The painting robots market is driven by several factors, including increased demand for automation, improved efficiency and productivity, cost savings, improved quality control, environmental regulations, advancements in technology, and growing demand from emerging economies.

- Automation is a growing trend in several industries, including automotive, aerospace, and construction. The painting robots offer higher accuracy, consistency, and speed than manual labor. Painting robots can work 24/7 without getting tired or taking breaks, which increases the efficiency and productivity of the painting process.

- Painting robots can reduce labor costs, minimize material waste, and reduce production time, which leads to significant cost savings for manufacturers. Painting robots are equipped with advanced sensors and technology that can monitor the painting process and ensure consistent quality, which is essential for many industries.

- Several countries have introduced strict environmental regulations that require manufacturers to reduce their emissions and waste. Painting robots can help minimize the environmental impact of the painting process. The painting robot industry is constantly evolving, with new technologies and features being introduced to improve the performance, safety, and efficiency of painting robots.

- Emerging economies such as China and India are experiencing rapid industrialization and are investing heavily in automation to increase their competitiveness in the global market. This trend is expected to drive the demand for painting robots in these regions.

Want to have a closer look at this market report? Click Here

Market Restraints

While the painting robots market has several drivers, some restraints may impact the growth of the market, including high initial investment costs, lack of skilled workforce, integration with existing production systems, safety concerns, limited flexibility, maintenance and repair costs, and regulatory compliance.

- Painting robots require significant capital investment, which may be a barrier for small and medium-sized enterprises (SMEs) or those with limited financial resources. The installation, programming, and maintenance of painting robots require specialized skills and expertise, which may be a challenge for companies that lack qualified personnel. Integrating painting robots with existing production systems may be challenging, as it requires a high level of customization and coordination.

- Painting robots are heavy machinery and can pose a risk to human operators if not properly maintained or operated. Safety protocols must be followed to prevent accidents. Painting robots are designed for a specific range of applications and may not be flexible enough to adapt to changing production requirements.

- Like any other equipment, painting robots require regular maintenance and repairs, which can be expensive and time-consuming. Painting robots must comply with several regulatory standards and requirements, which may vary by country and region. Failure to comply with these regulations may result in penalties or fines.

Segment Analysis

|

Segmentations

|

List of Sub-Segments

|

Segments with High Growth Opportunity

|

|

Type Analysis

|

Floor mounted painting robot, Wall mounted painting robot, Rail mounted painting robot, Other

|

Floor-mounted robots are currently dominating the painting robot market during the forecast period.

|

|

End-User Type Analysis

|

Automotive, Aerospace, Construction

|

Automotive industry is well-established and has been growing steadily during the forecast period.

|

|

Regional Analysis

|

North America, Europe, Asia-Pacific, and Rest of the World

|

Asia Pacific is currently the largest and fastest-growing regional market during the forecast period.

|

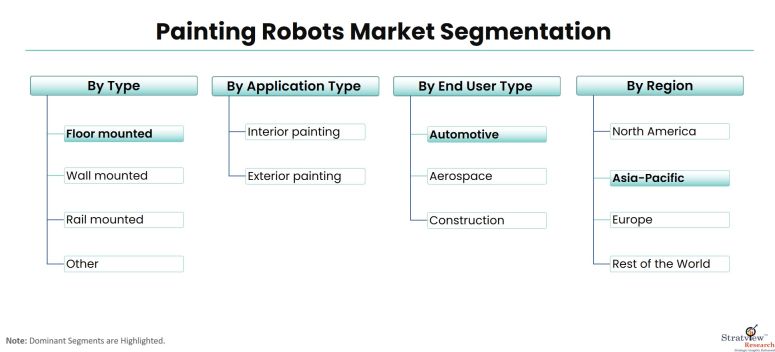

By Type

"Floor-mounted robots are currently dominating the painting robot market"

Floor-mounted robots are currently dominating the painting robot market. These robots are designed to be installed on the floor, and they can move in any direction to paint large and complex surfaces. Floor-mounted painting robots are widely used in the automotive industry for painting car bodies, as well as in the aerospace industry for painting aircraft parts. They offer high flexibility and can be customized to meet specific painting requirements, such as different types of coatings, colors, and textures. While wall-mounted and rail-mounted robots also have their applications, they are generally less common than floor-mounted robots. Wall-mounted robots are typically used for painting smaller parts and surfaces, while rail-mounted robots are used for painting long and narrow surfaces, such as pipes and tubes. Overall, the choice of robot type will depend on the specific painting application and requirements, as well as the available budget and resources.

By End-User Type

"Automotive industry is well-established and has been growing steadily"

The use of painting robots in the automotive industry is well-established and has been growing steadily in recent years, driven by the need for precision and consistency in painting car bodies. The aerospace industry is also a significant end-user of painting robots, particularly for painting large and complex aircraft components. The construction industry is a relatively smaller end-user of painting robots but is still growing as painting robots become more advanced and cost-effective.

Regional Analysis

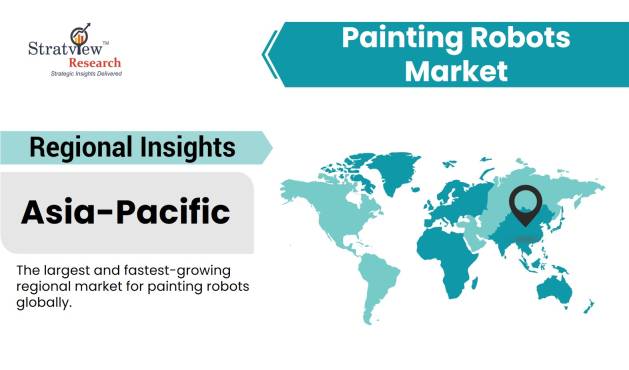

"Asia Pacific is currently the largest and fastest-growing regional market"

Asia Pacific is currently the largest and fastest-growing regional market for painting robots globally. The increasing adoption of automation in industries such as automotive, electronics, and aerospace, along with the rising labor costs, is driving the demand for painting robots in the region. In Asia Pacific, countries such as China, Japan, South Korea, and India are among the major markets for painting robots. North America and Europe are also significant markets for painting robots, driven by the demand from the automotive and aerospace industries.

The North American market for painting robots is experiencing steady growth, driven by the demand from the automotive and aerospace industries. The increasing focus on precision and quality in painting operations, along with the need to reduce labor costs, is driving the adoption of painting robots in these industries.

Another trend in the North American market is the use of collaborative painting robots, which can work safely alongside human workers, increasing efficiency and productivity. Additionally, the market is witnessing a rise in the use of smart painting robots equipped with advanced technologies such as artificial intelligence, machine learning, and computer vision, which can adapt to changing painting environments and improve overall performance.

Overall, the North American market for painting robots is expected to continue to grow in the coming years, driven by the need for increased efficiency, safety, and quality in painting operations.

Know the high-growth countries in this report. Register Here

Report Features

This report provides market intelligence in the most comprehensive way. The report structure has been kept such that it offers maximum business value. It provides critical insights into market dynamics and will enable strategic decision-making for existing market players as well as those willing to enter the market. The following are the key features of the report:

- Market structure: Overview, industry life cycle analysis, supply chain analysis.

- Market environment analysis: Growth drivers and constraints, Porter’s five forces analysis, SWOT analysis.

- Market trend and forecast analysis.

- Market segment trend and forecast.

- Competitive landscape and dynamics: Market share, Service portfolio, New Product Launches, etc.

- COVID-19 impact and its recovery curve

- Attractive market segments and associated growth opportunities.

- Emerging trends.

- Strategic growth opportunities for the existing and new players.

- Key success factors.

Market Segmentation

This report studies the market covering 12 years of trend and forecast. The report provides detailed insights into the market dynamics to enable informed business decision-making and growth strategy formulation based on the opportunities present in the market.

The painting robots market is segmented into the following categories:

By Type

- Floor mounted painting robot

- Wall mounted painting robot

- Rail mounted painting robot

- Other

By Application Type

- Interior painting

- Exterior painting

By End User Type

- Automotive

- Aerospace

- Construction

By Region

- North America (Country Analysis: The USA, Canada, and Mexico)

- Europe (Country Analysis: Germany, France, The UK, Russia, and the Rest of Europe)

- Asia-Pacific (Country Analysis: China, India, Australia, South Korea, and the Rest of Asia-Pacific)

- Rest of the World (Country Analysis: Saudi Arabia, Brazil, and Others)

Click Here, to learn the market segmentation details.

Customization Options

With this detailed report, Stratview Research offers one of the following free customization options to our respectable clients:

Company Profiling

- Detailed profiling of additional market players (up to three players)

- SWOT analysis of key players (up to three players)

Competitive Benchmarking

- Benchmarking of key players on the following parameters: product portfolio, geographical reach, regional presence, and strategic alliances

Custom Research: Stratview research offers custom research services across the sectors. In case of any custom research requirement related to market assessment, competitive benchmarking, sourcing and procurement, target screening, and others, please send your inquiry to [email protected]