Market Insights

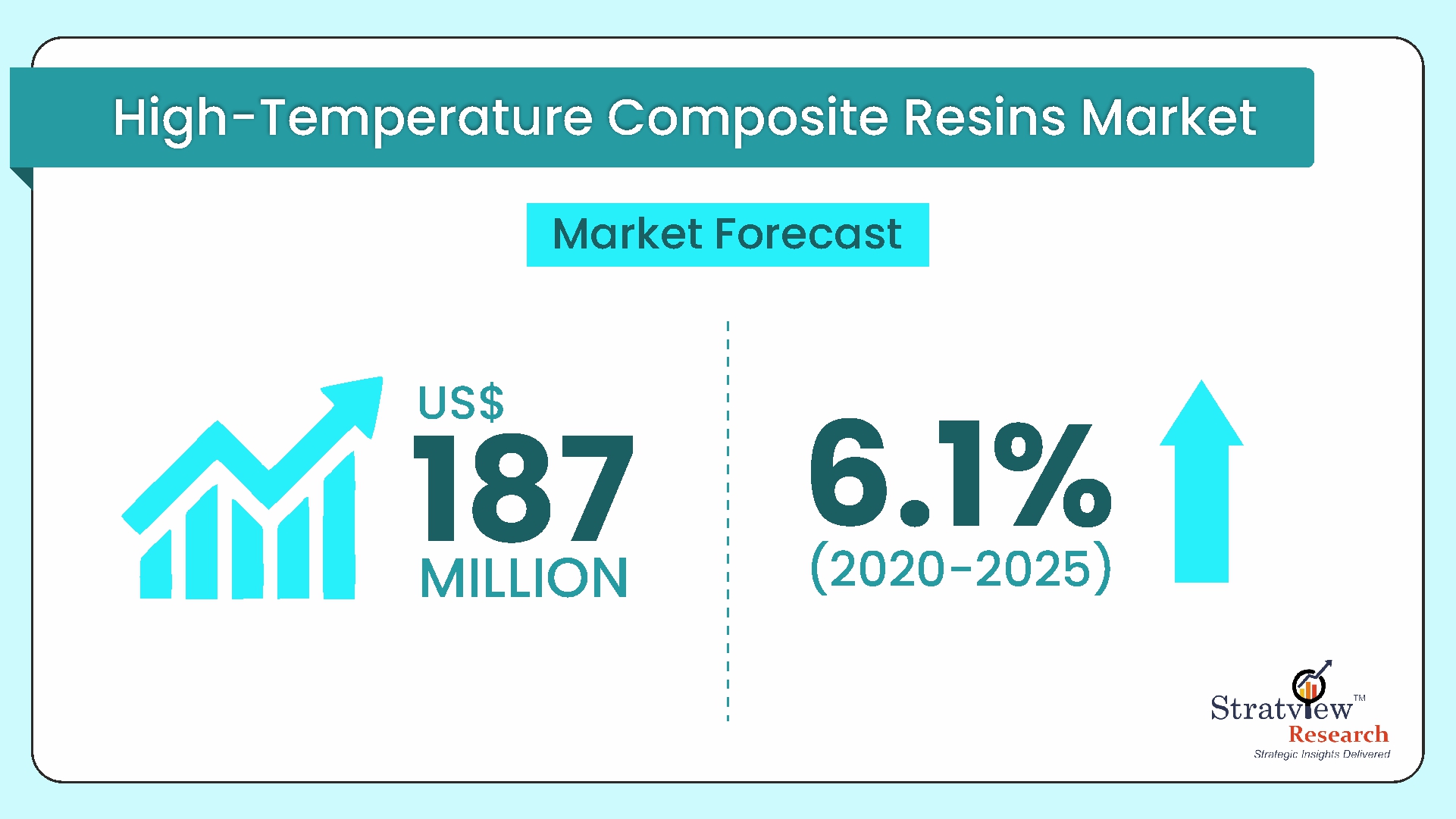

The high-temperature composite resin market was estimated at USD 126.5 million in 2019 and is likely to grow at a CAGR of 6.1% during 2020-2025 to reach USD 187.0 million in 2025.

Wish to get a free sample? Register Here

Market Dynamics

Introduction

A High-Temperature Composite Resin is a specialized type of resin material designed to withstand extreme heat and maintain its structural integrity in high-temperature environments. It is used in applications where traditional resins would fail or degrade under elevated temperatures. These resins are typically formulated with thermally stable polymers, additives, and reinforcements such as fibers or fillers that enhance their heat resistance and mechanical properties. High-temperature composite resins find applications in industries like aerospace, automotive, and manufacturing, where they are used in components subjected to high heat, such as engine parts, exhaust systems, and tooling for composite manufacturing processes.

Market Drivers

High-temperature resins have a long history in the composites industry with their usage in military and commercial aircraft engines. Nowadays, the composite stakeholders are betting on these resin technologies in other sections including airframes and other hot sections.

Increasing penetration of composites in the aerospace and automotive industries coupled with a greater demand for high-temperature composites, increasing production rates of high-temperature composite-rich F-35 aircraft, and superior performance benefits of high-temperature resins are the key factors proliferating the growth of the market.

High-temperature resin excels in the performance of composite parts and enhances the part’s ability to withstand extreme heat and harsh environmental conditions. Also, the resin performs better under fatigue than more brittle ceramics and is lighter than metals; therefore, the manufacturers have started adopting high-temperature resins instead of using ceramics and exotic metals. An aircraft engine is one of the biggest application areas of high-temperature composite resins as it is prone to extreme temperature and heat environments.

Newer jet engines and 5th generation fighter aircraft have pushed service temperature into the range of 600°F to 1000°F (316°C to 538°C), along with an increasing demand for composite materials to achieve excellent strength-to-weight ratio. Lockheed Martin’s F-35 is among the best-selling 5th generation aircraft, which has incorporated high-temperature composite resins. About 35% of the aircraft is made of composites, approximately 50% of which are high-temperature composites.

Segments Analysis

|

Segmentations

|

List of Sub-Segments

|

Segments with High Growth Opportunity

|

|

Resin Type Analysis

|

BMI, Cyanate Ester, Polyimide, Thermoplastics, and Others

|

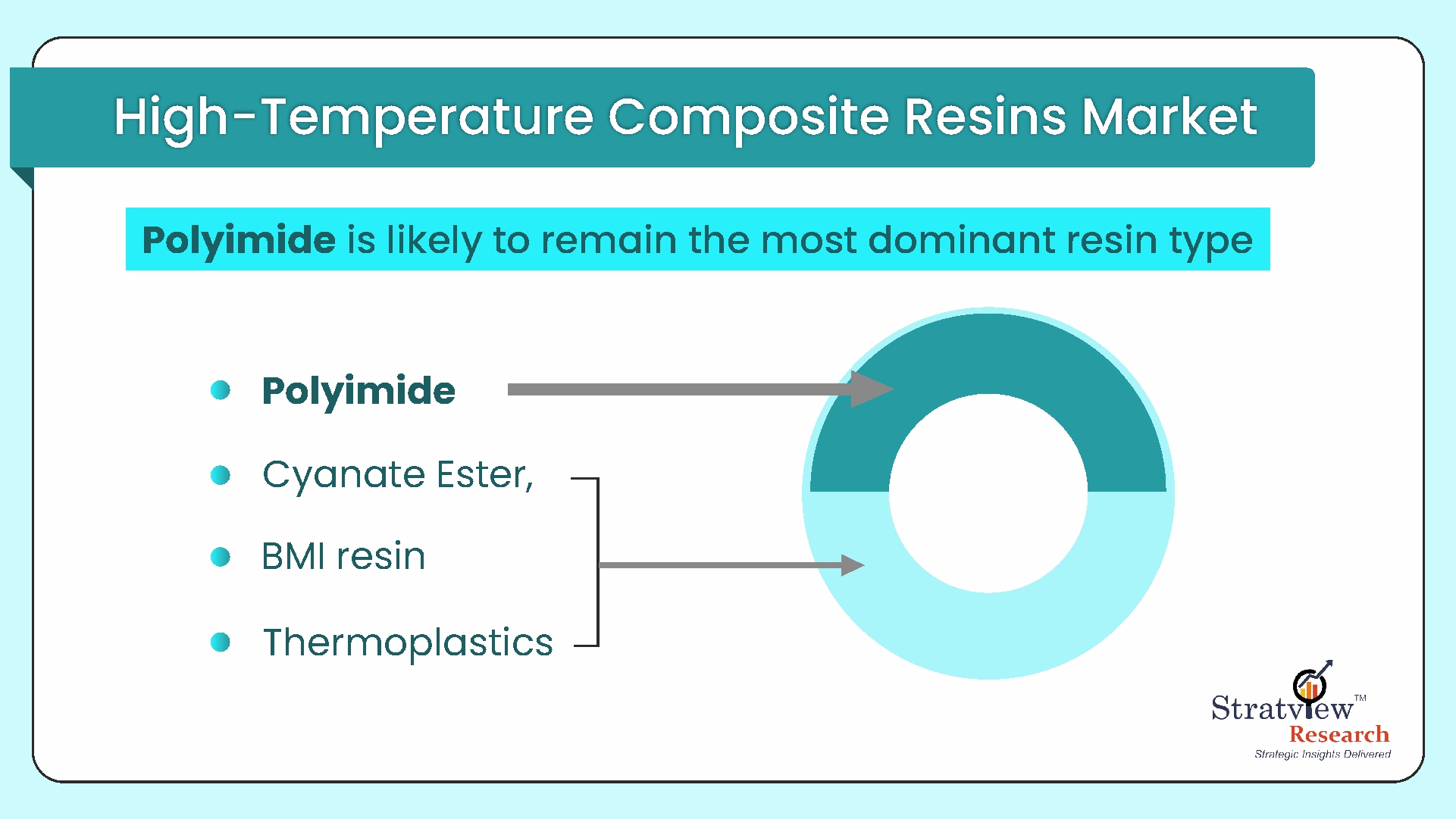

Polyimide resin is likely to remain the largest in terms of value over the next five years, with a market share of more than 50% during the forecast period.

|

|

End-Use Industry Type Analysis

|

Aerospace & Defense, Transportation, and Others

|

Aerospace & Defense is likely to remain the most dominant segment during the forecast period, with a market share of more than 90% during the forecast period.

|

|

Manufacturing Process Type Analysis

|

Prepreg Layup, RTM, and Others

|

Prepreg layup is expected to remain the dominant during the forecast period.

|

|

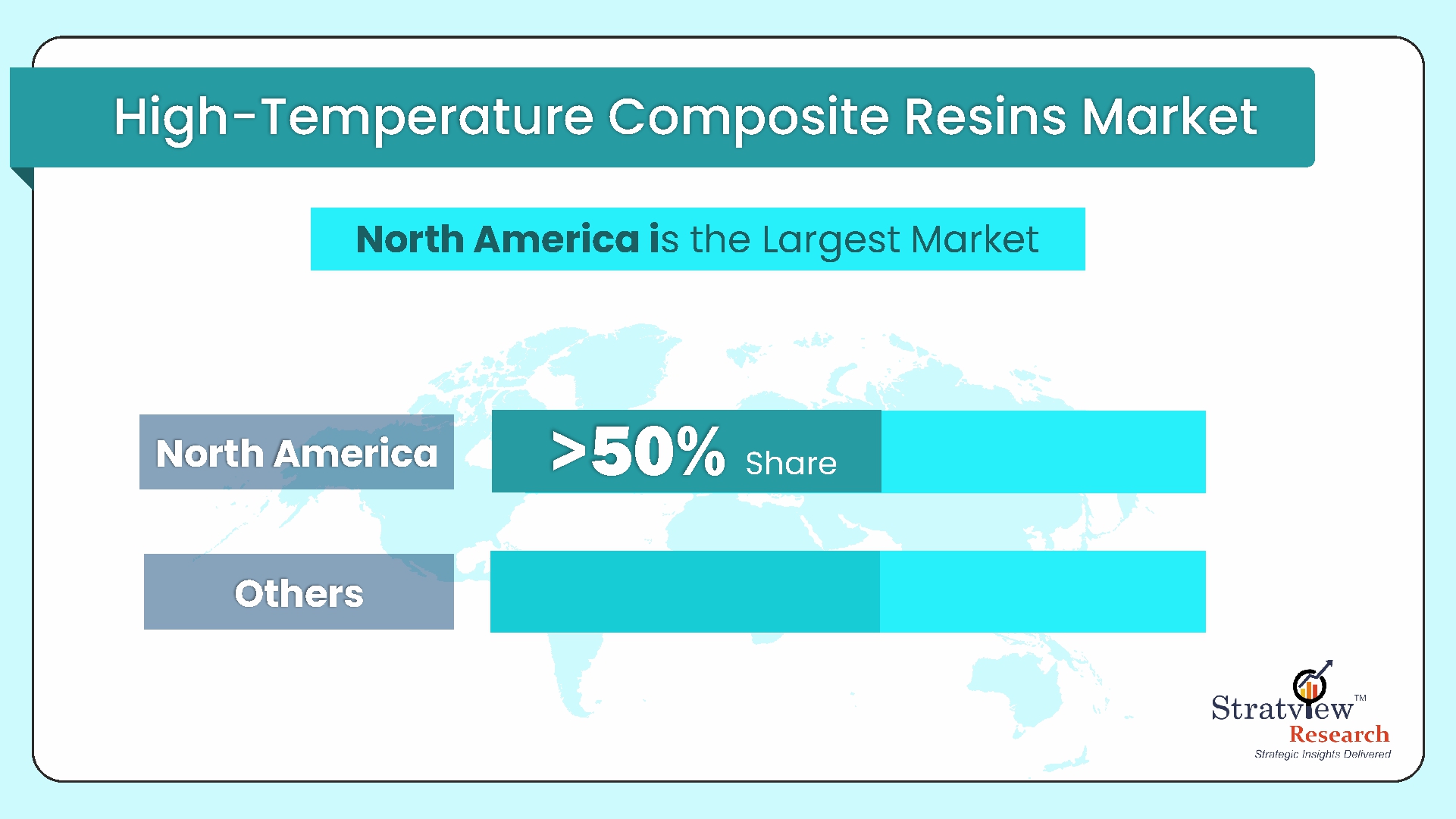

Regional Analysis

|

North America, Europe, Asia-Pacific, and Rest of the World

|

North America is projected to remain the largest market during the forecast period, with a market share of more than 50% during the forecast period.

|

By Resin Type

"Polyimide resin is likely to remain the largest in terms of value over the next five years, with a market share of more than 50% during the forecast period"

The high-temperature composite resins market is segmented as BMI, Cyanate Ester, Polyimide, Thermoplastics, and Others. BMI resin is likely to remain the most dominant resin type in terms of volume over the next five years. It is highly used in military aircraft engines as well as airframe applications, nacelles of business jet engines, tooling prepreg, and hot-air ducts.

Polyimide resin is likely to remain the largest in terms of value over the next five years, with a market share of more than 50% during the forecast period.

Polyimide composite parts can withstand continuous use up to 315°C (600°F) and intermittent use up to 480°C (900°F) and exhibit extremely high dimensional stability at elevated temperatures.

Want to get more details about the segmentations? Register Here

By End-Use Industry Type

"Aerospace & Defense is likely to remain the most dominant segment during the forecast period, with a market share of more than 90% during the forecast period"

The market is segmented based on the end-use industry types as Aerospace & Defense, Transportation, and Others. Aerospace & Defense is likely to remain the most dominant segment during the forecast period, with a market share of more than 90% during the forecast period. Increasing production rates of high-temperature composite-rich fighter aircraft F-35 (Joint Strike Fighter) is likely to create an impetus in the demand for high-temperature composites in the industry.

Lockheed Martin announced it has experienced a 40% increase in deliveries of F-35 aircraft in 2018 over the previous year. The company is likely to further increase its annual deliveries from 91 aircraft in 2018 to an expected delivery of 160 aircraft in 2023. Another key application area of high-temperature composite resin is the tooling prepreg where BMI is gaining traction.

By Manufacturing Process Type

"Prepreg layup is expected to remain the dominant during the forecast period"

The high-temperature composite resins market is segmented as Prepreg Layup, RTM, and Others. Prepreg layup is expected to remain the dominant process for manufacturing composite parts made using high-temperature composite resins. The process is the most widely preferred process for manufacturing critical parts in the aerospace & defense industry, where high-temperature resin systems are used. Prepreg layup offers various advantages, such as consistent material properties, high fiber volume, flexibility in fiber orientation, low-void content, and easy-to-operate on complicated shapes.

Regional Analysis

"North America is projected to remain the largest market during the forecast period, with a market share of more than 50% during the forecast period"

Based on the regions, North America is projected to remain the largest market during the forecast period, with a market share of more than 50% during the forecast period, driven by the world’s leading aircraft OEMs, aero-engine manufacturers, tier players, and material suppliers. The USA is the growth engine of the region’s market. Lockheed Martin has opened a new manufacturing facility to produce its high-geocomposite-rich F-35 aircraft in Pinellas Park, Florida, the USA, to raise the existing production rate. There is a current US government inventory objective of 2,456 F-35 aircraft for the U.S. Air Force, U.S. Marine Corps, and U.S. Navy; commitments from our eight international partners, and three international customers; as well as expressions of interest from other countries.

Europe is projected to remain the second-largest market for high-temperature composite resins during the forecast period. Dassault Aviation, BAE Systems, and Airbus Group are some of the key OEMs in the region, which are driving the demand for high-temperature composite resins in the European market.

Want to know which region offers the best growth opportunities? Register Here

Key Players

The supply chain of this market comprises raw material suppliers, high-temperature resin manufacturers, prepregs & compounders, tier players, OEMs, and airliners.

The key high-temperature composite resins manufacturers include-

The development of low-cost high-temperature composite resins with ease of manufacturing processes; reduced operational cost; and formation of strategic alliances are the key strategies adopted by the players to gain a competitive edge in the market.

Note: The above list does not necessarily include all the top players in the market.

Are you the leading player in this market? We would love to include your name. Write to us at [email protected]

Research Methodology

- This strategic assessment report, from Stratview Research, provides a comprehensive analysis that reflects today’s high-temperature composite resin market and future market possibilities for the forecast period.

- The report segments and analyzes the market in the most detailed manner to provide a panoramic view of the market.

- The vital data/information provided in the report can play a crucial role for market participants as well as investors in the identification of the low-hanging fruits available in the market as well as to formulate growth strategies to expedite their growth process.

- This report offers high-quality insights and is the outcome of a detailed research methodology comprising extensive secondary research, rigorous primary interviews with industry stakeholders, and validation and triangulation with Stratview Research’s internal database and statistical tools.

- More than 1,000 authenticated secondary sources, such as company annual reports, fact books, press releases, journals, investor presentations, white papers, patents, and articles, have been leveraged to gather the data.

- We conducted more than 15 detailed primary interviews with market players across the value chain in all four regions and industry experts to obtain both qualitative and quantitative insights.

Report Features

This report provides market intelligence in the most comprehensive way. The report structure has been kept such that it offers maximum business value. It provides critical insights into market dynamics and will enable strategic decision-making for existing market players as well as those willing to enter the market. The following are the key features of the report:

- Market structure: Overview, industry life cycle analysis, supply chain analysis.

- Market environment analysis: Growth drivers and constraints, Porter’s five forces analysis, SWOT analysis.

- Market trend and forecast analysis.

- Market segment trend and forecast.

- Competitive landscape and dynamics: Market share, Service portfolio, New Product Launches, etc.

- COVID-19 impact and its recovery curve

- Attractive market segments and associated growth opportunities.

- Emerging trends.

- Strategic growth opportunities for the existing and new players.

- Key success factors.

Market Segmentation

This report studies the market covering 12 years of trend and forecast. The report provides detailed insights into the market dynamics to enable informed business decision-making and growth strategy formulation based on the opportunities present in the market.

The high-temperature composite resin market is segmented into the following categories:

By Resin Type

- BMI

- Cyanate Ester

- Polyimide

- Thermoplastics

- Others

By End-Use Industry Type

- Aerospace & Defense

- Transportation

- Others

By Manufacturing Process Type

By Region

- North America (Country Analysis: The USA, Canada, and Mexico)

- Europe (Country Analysis: Germany, France, The UK, Russia, and the Rest of Europe)

- Asia-Pacific (Country Analysis: China, India, Australia, South Korea, and the Rest of Asia-Pacific)

- Rest of the World (Country Analysis: Saudi Arabia, Brazil, and Others)

Customization Option

With this detailed report, Stratview Research offers one of the following free customization options to our respectable clients:

Company Profiling

- Detailed profiling of additional market players (up to three players).

- SWOT analysis of key players (up to three players).

Competitive Benchmarking

- Benchmarking of key players on the following parameters: Product portfolio, geographical reach, regional presence, and strategic alliances.

Custom Research: Stratview Research offers custom research services across sectors. In case of any custom research requirement related to market assessment, competitive benchmarking, sourcing and procurement, target screening, and others, please send your inquiry to [email protected].