Market Insights

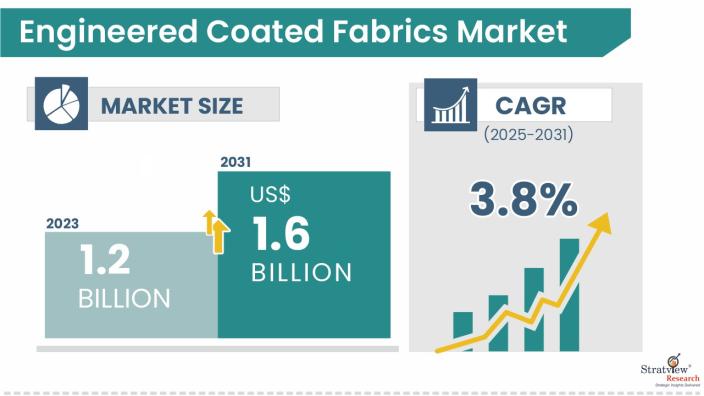

The engineered coated fabrics market was estimated at USD 1.2 billion in 2023 and is likely to grow at a CAGR of 3.8% during 2025-2031 to reach USD 1.6 billion in 2031.

Wish to get a free sample? Register Here

Market Dynamics

Introduction

The engineered coated fabrics market is growing rapidly as demand in many related industries continues to surge. These fabrics, enhanced with a specialized coating, offer superior performance features, including durability, abrasion resistance, and an improved look. Because of their rigorous application demands, coated fabrics are employed in several industries, such as automotive, aerospace, marine, and construction. Besides, advancements in coating formulas and production technologies have also acted as growth stimulants for the material. Therefore, engineered coated fabrics are projected to grow steadily since the global market moves towards using lightweight and high-performance products.

After the COVID-19 pandemic, the healthcare industry has significantly increased the use of engineered coated fabrics, driven by growing demand for hygiene and infection control products such as PPE, gloves, and other protective gear.

Market Drivers

Many factors have favored the growth of the engineered coated fabrics market. The automotive industry plays a significant role; the progressing demand for coated fabrics for automotive interiors and airbags is the motivating factor. In the same way, engineered coated textile materials are widely applied in aerospace and marine industries because they can withstand adverse environmental factors and possess fire-retardant properties. Moreover, advancements in coating technology like nanotechnology and fluoropolymer coatings enhance the efficacy and serviceability of these fabrics, which ultimately spurs the market growth.

Recent Market JVs and Acquisitions:

There are some strategic alliances, including M&As, JVs, etc., have been performed over the past few years.

- In 2021, Trelleborg acquired Alpha Engineered Composites, a privately held US-based company. This acquisition has given Trelleborg access to heat-resistant silicone-coated fabrics, allowing the company to expand into new markets in the coatings category.

- In 2020, Freudenberg acquired Low & Bonar, a global manufacturer of technical textiles, to strengthen its performance material segment.

- In 2018, Trelleborg, a global leader in industrial polymer solutions, acquired Laminating Coating Technologies, a coatings manufacturer. This acquisition enabled Trelleborg to strengthen its position in the aerospace market.

Segment Analysis

|

Segmentations

|

List of Sub-Segments

|

Segments with High Growth Opportunity

|

|

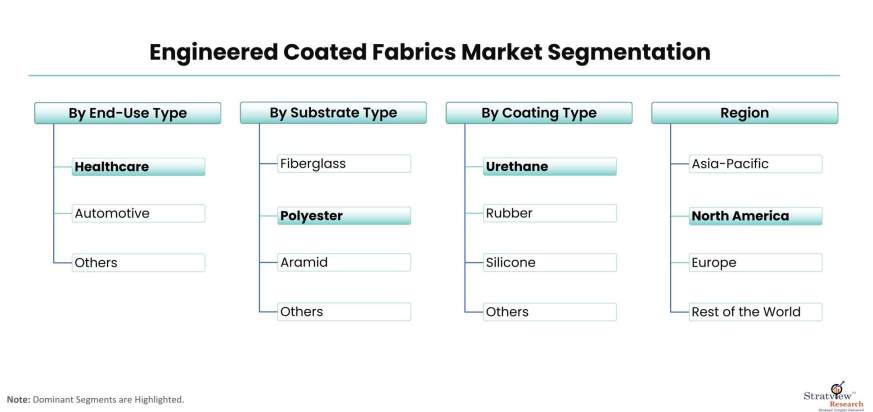

End-Use-Type Analysis

|

Automotive, Healthcare, Aerospace, Marine, Industrial Safety, and Other End-Uses.

|

Healthcare is expected to be the most significant end-use type during the forecast period.

|

|

Substrate-Type Analysis

|

Polyester, Fiberglass, Aramid, Polyamide, and Other Substrate Types

|

Polyester is projected to be the dominant substrate throughout the forecast period.

|

|

Coating-Type Analysis

|

Urethane, Rubber, Silicone, and Other Coating Types

|

Urethane is projected to be the most preferred coating in the market during the forecast period.

|

|

Region Analysis

|

North America, Europe, Asia-Pacific, and The Rest of the World

|

North America is anticipated to retain its position as the dominant region during the forecast period.

|

By End-Use Type

“Healthcare is expected to remain the dominant aircraft type in the market during the forecast period.”

- Healthcare is the largest and fastest-growing end-use industry due to its rising demand for hygiene and infection control applications, such as gloves, PPE, and medical equipment covers. The increased focus on minimizing cross-contamination and patient safety, particularly after the COVID-19 outbreak, has contributed to the engineered coated fabrics market expansion.

- The aerospace industry is also set to expand steadily due to the increasing demand for light, strong, high-performance materials utilized in aircraft interiors, seating, escape slides, aerostats, and other applications.

- It should also be noted that marine and industrial safety also has the presence of engineered coated fabrics. These include switch crafts, inflatable boats, protective clothing, garments, protective jackets, gloves, other garments, and hovercrafts.

By Substrate Type

“Polyester is expected to remain the dominant substrate type in the market during the forecast period.”

- Polyester is expected to remain the most significant substrate type due to its durability, reasonable price, and versatility across various applications. Due to its excellent characteristics, such as wear, stretching, and resistance to environmental factors, polyester is mainly used in health care and the automotive industry, especially in seats, chairs, etc., as they require durability and service strength.

- Fiberglass is expected to be the fastest-growing substrate as it has high strength, heat resistance, and low-density properties. These characteristics make fiberglass increasingly widely used in higher-performance applications such as the aerospace industry and industrial uses such as protective clothing and glows in which lightweight, high-strength materials are desirable.

By Coating Type

“Urethane is expected to remain the dominant coating type, whereas silicon remains the fastest-growing of the market during the forecast period.”

- Properties such as increased flexibility, durability, abrasion resistance, and chemical and environmental resistance make urethane-coated fabrics suitable for use in several industries, such as healthcare, automotive interiors, and protective clothing.

- Urethane coatings offer good water resistance while being somewhat permeable. Its fabric has promising applications in hospitals (seats, chairs, mattresses) and for industrial safety.

- Silicone-coated fabrics are experiencing a high growth rate because of factors such as high heat resistance, biocompatibility, and water resistance. These characteristics make silicone suitable for high-temperature applications, such as fire-protective clothes.

Regional Insights

“North America is projected to remain the largest market for aerospace-engineered coated fabrics during the forecast period.”

- North America is the largest region in the engineered coated fabric industry due to highly developed industries and superior technologies. The U.S. and Canada are dominant contributors, driven by increasing demand across various industries and favorable regulatory environments.

- High safety and environmental standards, particularly in North America, have contributed to advancements in engineered coated fabrics for escape slides, protective apparel, and medical and industrial products.

- Asia-Pacific is a fast-growing region owing to its growing economy, increased adoption of technology, and industrialization. Primary markets are China, Japan, and India, owing to a large consumer pool and a strong focus on the technical and developmental front.

Know the high-growth countries in this report. Register Here

Key Players

The market is highly fragmented, with the presence of over 500 players. Most of the major players compete in some of the governing factors, including price, service offerings, regional presence, etc. The following are the key players:

Here is the list of the Top Players (Based on Dominance)

- Continental

- Trelleborg

- Freudenberg

- Orca, Pennel & Flipo

- Uniroyal Global

- Omnova Solutions Inc.

- Fothergill Engineered Fabrics Ltd

- Cooleygroup

- Morbern

- Spradling International

Note: The above list does not necessarily include all the top players in the market.

Are you the leading player in this market? We would love to include your name. Please write to us at sales@stratviewresearch.com

Research Methodology

This strategic assessment report, from Stratview Research, provides a comprehensive analysis that reflects today’s engineered coated fabrics market realities and future market possibilities for the forecast period of 2025 to 2031. After a continuous interest in our engineered coated fabrics market report from the industry stakeholders, we have tried to further accentuate our research scope to the engineered coated fabrics market to provide the most crystal-clear picture of the market. The report segments and analyses the market in the most detailed manner to provide a panoramic view of the market. The vital data/information provided in the report can play a crucial role for the market participants as well as investors in the identification of the low-hanging fruits available in the market as well as to formulate the growth strategies to expedite their growth process.

This report offers high-quality insights and is the outcome of a detailed research methodology comprising extensive secondary research, rigorous primary interviews with industry stakeholders, and validation and triangulation with Stratview Research’s internal database and statistical tools. More than 1000 authenticated secondary sources, such as company annual reports, fact books, press releases, journals, investor presentations, white papers, patents, and articles, have been leveraged to gather the data. We conducted more than 15 detailed primary interviews with the market players across the value chain in all four regions and industry experts to obtain both qualitative and quantitative insights.

Report Features

This report provides market intelligence most comprehensively. The report structure has been kept so that it offers maximum business value. It provides critical insights into market dynamics and will enable strategic decision-making for existing market players as well as those willing to enter the market. The following are the key features of the report:

- Market structure: Overview, industry life cycle analysis, supply chain analysis.

- Market environment analysis: Growth drivers and constraints, Porter’s five forces analysis, SWOT analysis.

- Market trend and forecast analysis.

- Market segment trend and forecast.

- Competitive landscape and dynamics: Market share, Service portfolio, New Product Launches, etc.

- COVID-19 impact and its recovery curve

- Attractive market segments and associated growth opportunities.

- Emerging trends.

- Strategic growth opportunities for the existing and new players.

- Key success factors.

Market Segmentation

This report studies the market, covering a period of 12 years of trend and forecast. The report provides detailed insights into the market dynamics to enable informed business decision-making and growth strategy formulation based on the opportunities present in the market.

The engineered coated fabrics market is segmented into the following categories:

By End-Use Type

- Automotive

- Healthcare

- Aerospace

- Marine

- Industrial Safety

- Other End-Uses

By Substrate Type

- Polyester

- Fiberglass

- Aramid

- Polyamide

- Other Substrate Types

By Coating Type

- Urethane

- Rubber

- Silicone

- Other Coating Types

By Region

- North America (Country Analysis: The USA, Canada, and Mexico)

- Europe (Country Analysis: Germany, France, The UK, Russia, and Rest of Europe)

- Asia-Pacific (Country Analysis: Japan, China, India, and Rest of Asia-Pacific)

- Rest of the World (Country Analysis: Brazil and Others)

Click here to learn the market segmentation details.

Report Customization Options

With this detailed report, Stratview Research offers one of the following free customization options to our respectable clients:

Company Profiling

- Detailed profiling of additional market players (up to three players)

- SWOT analysis of key players (up to three players)

Competitive Benchmarking

- Benchmarking of key players on the following parameters: Service portfolio, geographical reach, regional presence, and strategic alliances.

Custom Research: Stratview Research offers custom research services across Industries. In case of any custom research requirement related to market assessment, competitive benchmarking, sourcing and procurement, target screening, and others, please send your inquiry to sales@stratviewresearch.com.